Working temperature of LEDs and LED driver – electric street light

Working temperature of LEDs and LED driver – electric street light

Introduction

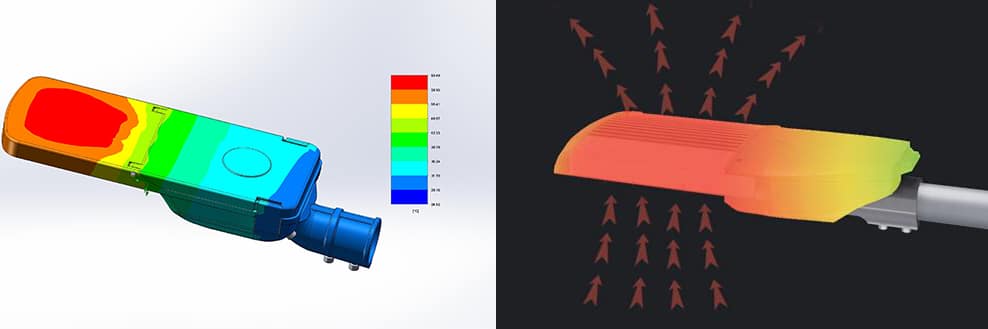

Generally speaking, LED lamps will generate a certain amount of heat when running, but compared to traditional light sources (such as incandescent lamps), LEDs usually generate lower temperatures. However, LED lamps still need to operate within a reasonable temperature range. If the designed operating temperature is exceeded, the lamp may not operate properly or even be damaged due to heat accumulation. The temperature of LED lamps is affected by many factors, including the power of LED lamps, LED power supply performance, heat dissipation design of lamps, ambient temperature, and working hours. The higher the power of the LED chips /the worse the power supply performance/the unreasonable heat dissipation design of the lamp/the higher the ambient temperature and the longer the working time, the higher the temperature of the entire lamp may be. This is bound to have an adverse effect on the main components of the lamp (such as LEDs and power supply) which may finally cause electric street light outage ( Click here to view the video of the Leaf LED Street Light Fixtures. ). In order to ensure the long-term stable operation of LED lamps, designers usually consider reasonable design, including structure, circuit and heat dissipation, to control the temperature of the LED chip and power supply to prevent overheating. Below is the thermal camera of ZGSM Rifle and H series electric street lights.

Why we should care about the temperature?

The temperature of LED lamps involves many aspects such as the working temperature of the LED chip and power supply, the shell temperature, the ambient temperature, and the usage conditions. Designers need to take these factors into consideration to ensure that LED lamps work within a safe range and have good heat dissipation performance to ensure long-term stable operation – prevent street light outage.

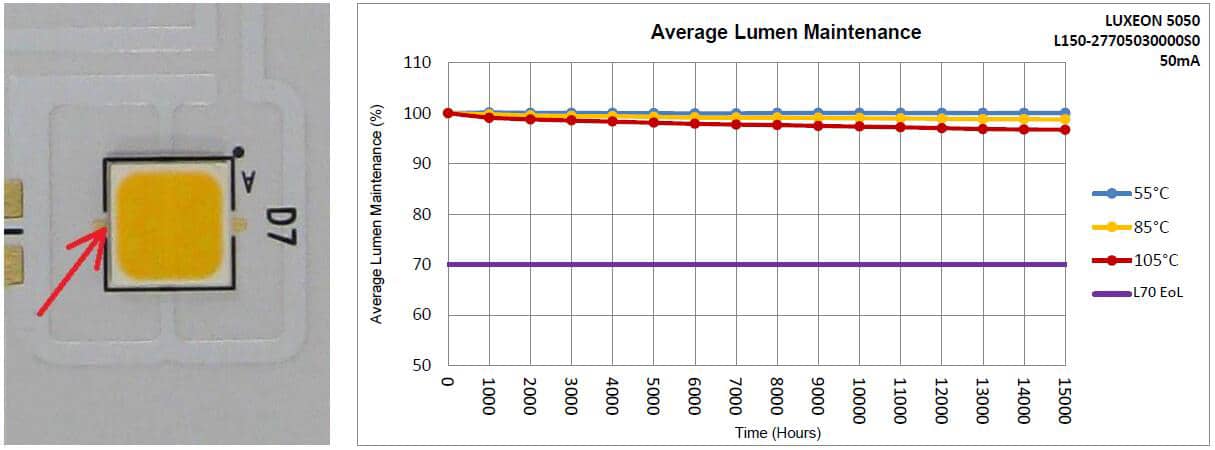

- Excessive temperature will aggravate the light decay of LED chips. By referring to the LM80 report of the lamp bead, we can know that the higher the temperature, the worse the L70 lifetime result, that is, the more serious the light attenuation is.

- Excessive temperature will cause the failure rate of LED chips to increase. Studies have shown that excessive heat can cause thermal stress on LED components (such as solder joints and circuit boards), leading to failure and damage to the entire module.

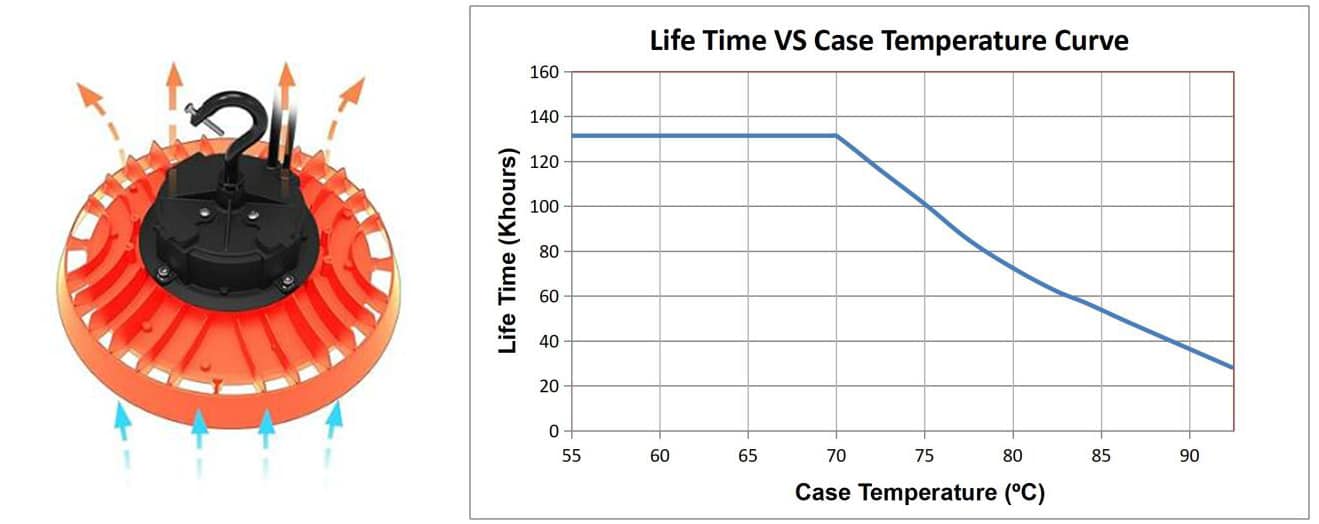

- Excessive temperature will cause the failure rate of LED power supply to increase. By referring to the power supply specifications, we can find that as the temperature increases, the MTBF (Mean Time Between Failures) will decrease.

- The lower the ambient temperature of the lamp when it is designed, the worse the effect may be when used in extreme environments. For example, the ambient temperature in some countries in the Middle East may rise above 40 degrees. We need to consider this situation when designing lighting fixtures.

Working temperature of LED chips

LED chips mainly convert electrical energy into light energy. During this process, part of the electrical energy is converted into heat energy. The LED chips will therefore gradually generate heat, and their temperature will gradually rise. When the heat generated by the lamp beads and the heat lost reach a balance, the temperature will no longer change. If the temperature remains within the rated operating temperature range of the LED lamp bead, the LED is in normal working condition. However, within the rated operating temperature range, the higher the temperature, the more obvious the light attenuation (referring to the attenuation of light output). Therefore, it is necessary to take appropriate design and heat dissipation measures to control the temperature of the LED lamp beads to ensure the life and performance of the LED. Generally speaking, the rated operating temperature range of LEDs is usually between -40 and 105°C. If the temperature exceeds 105°C, the LED lamp beads may be at risk of damage. As shown in the figure below, it shows the light attenuation of LED at different temperatures.

Temperature range data table of different LED chips

Different types of LED chips and package designs will affect their temperature resistance. The following is a comparison of the operating temperature ranges of common LED models:

| LED Model | Operating Temperature Range | Maximum Junction Temperature (Tj) | Applicable Environment |

| Cree XLamp XHP70.3 | -40°C~+125°C | 150°C | Roadway, high bay, stadium, runway and architectural lighting |

| Osram Duris S5 | -40°C~+100°C | 125°C | Indoor, entertainment and outdoor lighting |

| Lumileds LUXEON 5050 | -40°C~ +105°C | 125°C | Street lights, high bays, floodlights |

| Samsung LM301H | -40°C ~ +85°C | 110°C | Indoor farm lighting, horticultural lighting, greenhouse lighting |

Working temperature of LED driver

As the core component of LED lamps, the main function of LED power supply is to convert alternating current into direct current to supply the electrical energy required for the normal operation of LED chips. During this conversion process, various components of the LED power supply will consume electrical energy, and part of the energy will be converted into heat and released. Normally, the operating temperature of LED power supplies is not too high. However, under special circumstances, such as when the working environment temperature is high or the LED radiator is too close to the LED power supply, the temperature of the LED power supply may rise and the LED power supply may not work properly. Generally speaking, the best working temperature of LED power supply is about 60 degrees. At this temperature, the service life of LED power supply is longer. In general, the designed operating temperature of LED power supply is between -40 and 80°C. If the temperature exceeds 80℃, the LED power supply may be damaged. As shown in the figure below, the life curve of the LED power supply at different temperatures is shown.

Temperature resistance of LED drivers of different brands

The operating temperature range of LED drivers varies by brand and model. Below is a comparison of the operating temperature range and efficiency of common LED drivers:

| Drive Brand | Operating Temperature Range | Efficiency | Protection Mechanism | Applicable Scenarios |

| Mean Well HLG-480H | -40°C ~ +90°C | 95.5% | OTP (Over Temperature Protection) | Indoor lighting and outdoor lighting |

| Philips Xitanium Xi FP 75W | -40°C ~ +85° | 90% | Automatic power reduction | Area lighting, tunnel lighting, industrial lighting |

| Inventronics EUD-200S105BVA | -40°C ~ +89°C | 94.5% | OVP, SCP, OTP | High bay lighting, high mast lighting, arena lighting and road lighting |

| Tridonic Driver LCO 120W | -40°C ~ +85°C | 90.5% | ETM | Tunable white light applications, road, street and industrial tunnel lighting |

Extreme weather conditions cause considerable variations in LED driver performance. Wide-temperature drivers, like those made by Mean Well and Inventronics, have an improved circuit architecture and effective heat dissipation solutions that allow them to function steadily under extreme conditions between -40°C and 90°C. The Inventronics EUD series, for instance, has a unique low-temperature starter technology to guarantee quick startup even in very cold environments. By lowering thermal resistance, this technology also increases dependability in high-temperature settings. The higher the operating temperature of the LED driver, the shorter the lifetime of the LED driver.

Some Tridonic models, for example, claim that you need to chill the air with forced air. Overtemperature protection is particularly important in real-world engineering because it keeps equipment from getting too hot and breaking. When picking electric street light for places like deserts or very cold areas, you need to think about more than simply the driver's temperature range. You should also consider about how effectively it keeps itself cool and how well it protects itself to make sure the lighting system performs properly for a long period.

Working temperature of LED lamps (relationship between LEDs, LED power supply and LED lamps)

The operating temperature of LED lamps is an important factor in ensuring their stable operation and long-term performance. When designing LED lamps, the operating temperatures of the LED chip, power supply and housing, as well as the temperature of the surrounding environment, must be comprehensively considered. For example, if the nominal maximum operating temperature of the lamp is 50°C, exceeding this temperature will increase the risk of damage to the lamp (including power supply and LEDs). How is this temperature confirmed? ZGSM is mainly determined by referring to the performance of LED lamps(street lights and flood lights) and power supplies at different temperatures. For example, at 50°C, the Ts point temperature of the LED lamp is 85°C. We can infer that the temperature of the Tj point is close to 100°C. This temperature is close to the maximum operating temperature recommended by the LEDs manufacturer, so 50°C is confirmed as the lamp. the maximum operating temperature. Because it is not difficult to understand that when the ambient temperature exceeds 50°C, the temperature of the main components of the lamp (such as LEDs and power supply) will further rise. Although it may not have much impact on the lamps in a short period of time, long-term high-temperature operation will inevitably lead to component aging and damage.

Electric street light overheating solutions

To make LED streetlights ( Learn more about ZGSM Electric street light ) more resistant to heat, the core parts and thermal management must be designed to work together. LED chips that can handle high temperatures, like the Osram Duris S5 or Cree XHP70.3, are best since their specific package can handle temperatures from -40°C to +105°C. These chips have a built-in NTC thermistor that lets them keep an eye on the temperature in real time. They work with a Mean Well HLG or Inventronics EUD series wide-temperature driver. If the junction temperature goes over the set point, the OTP protection kicks in automatically and lowers the output current to 60% of the rated value to stop thermal runaway. The heat dissipation system has a multilayer design. The LED module is tightly glued to a 2mm-thick aluminum substrate using a silicone grease that is very conductive (thermal conductivity >3W/m·K). Fluid simulation is used to improve the heat sink fins such that they have 40% more effective surface area. Tests have demonstrated that this technique keeps the chip junction temperature consistent within the safety level of 85°C when the electric street light is on all the time in an environment with a temperature of 50°C. This cuts down on light decay by 70% compared to standard designs.

Advantages of separating cavities for LEDs and LED driver of electric street light

ZGSM believes that the separation of the light-emitting cavity and the power supply cavity in LED lamps has many advantages, the most important of which is to reduce the heat interaction between the LED chips and the LED power supply. The heat generated by the LED chips will not be conducted to the LED power supply, preventing the LED power supply from exceeding the maximum operating temperature and stopping working. Because LED power supplies usually have overheating protection, once the temperature exceeds the limit, the power supply will automatically cut off the output. Similarly, the heat generated by the LED power supply will not be conducted to the LED chips, preventing the LED chips from not dissipating heat in time, accelerating light decay and causing damage to the chips. Therefore, it is necessary to ensure that there is a certain distance between the LED light source and the power supply to ensure that the heat generated by each does not interfere with each other. In addition, there are other benefits to separating the light-emitting cavity and the power cavity. Below is the design of our Falcon electric street light with separating cavities.

More convenient maintenance and replacement: The partition design makes the maintenance and replacement of LED lamps more convenient. When the LED power supply fails, we only need to open the power supply cavity for replacement. This process does not involve the disassembly of the light-emitting cavity, which simplifies the maintenance process and avoids the possible impact of disassembly on the performance of the lamp (such as waterproof performance, cleaning of the lamp lens, etc.). The same is true when replacing LED chips, although LEDs rarely fail.

Improved design flexibility: Separating the light-emitting cavity and the power cavity also provides design flexibility. In the light-emitting cavity part, we only need to consider the structural design and component installation of the light-emitting unit. In the power cavity part, only the structural design and component installation of the power supply, surge protection and base need to be considered. Because the two are separated, manufacturers can design higher-wattage lamps in smaller housings or achieve more functions while maintaining performance.

ZGSM LED lights

ZGSM's products must undergo temperature testing. We will consider this in the early stages of lighting design. After the model is made, we will test the temperature of the entire lamp’s LED chips (Ts) and the temperature of the LED power supply (Tc) to evaluate the rationality of the design. After the design is completed, we will entrust a third-party experiment to conduct the ISTMT test, which is a report on Ts and Tc temperature. In addition, we offer other reports including LM82, LM84, and TM21 that are also related to the temperature of the fixture. The following are ZGSM products(electric street lights, post top lights, flood lights, canopy lights and high mast lights), please contact us if you need them.

Summary

As can be learned from the previous sections, LED chips and power supplies can work normally within an appropriate temperature range. Therefore, when designing a lamp, it is necessary to consider its usage environment to ensure that the temperature does not exceed its specified limit value. The working temperature of LED chips and power supply directly affects the overall performance and life of LED lamps. Effective temperature management is critical to the stability and long-term reliability of LED systems. In the ISTMT report of electric street light ( Please review case studies of LED light street. ) , we can obtain the Ts temperature data of the LED chip and the Tc temperature data of the power supply. ZGSM evaluates the performance of the LED system based on these data, and if necessary, adjusts the driving current of the LEDs, lamp structure and power supply. At the same time, we need to ensure that the light-emitting cavity and power cavity of the LED lamp are independent of each other as much as possible. This helps to prevent the interaction between the heat of the power supply and the heat of the LED chips, thereby extending the service life of each component. Welcome to contact ZGSM for more relevant information.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483