Constant current LED driver or constant voltage LED driver

Constant current LED driver or constant voltage LED driver

Introduction

LEDs can be powered by low-voltage direct current, while power grids typically provide high-voltage alternating current. The main purpose of the LED driver is to change this high voltage AC into a low voltage DC that can drive the LED. That is, the LED driver supplies power to these LED chips (loads) in the LED lamp. And the quality of an LED fixture depends on its driver. They can be divided into two main types: constant current (CC) drivers and constant voltage (CV) drivers. For constant current drivers, the output current is fixed by the driver, while the output voltage varies according to the LED load. For the constant voltage driver, under the allowable load condition, the output voltage is constant and will not change with the change of the load. Constant current LED drivers are ideal for outdoor, industrial and commercial lighting applications. Constant voltage drivers are more commonly found in multi-color displays, and series-parallel combination LED strips with built-in resistors or other current limiting devices, etc.

There are many factors to consider when choosing the best LED driver for you, an important choice is to choose between constant current LED driver and constant voltage LED driver. As we all know, LED drivers are considered constant current devices, so why do LED driver manufacturers also provide constant voltage drivers for LEDs? How do we distinguish between the two?

Constant current LED driver or constant voltage LED driver

An LED driver is what supplies and regulates the power necessary to keep the LEDs operating in a safe and consistent manner. Both constant current and constant voltage drivers are viable options for powering LED light sources, the difference lies in the way they provide power. Knowing the difference between the two types can:

- Get the LEDs to be properly powered

- Avoid serious damage to LED investment

What is a constant current LED driver?

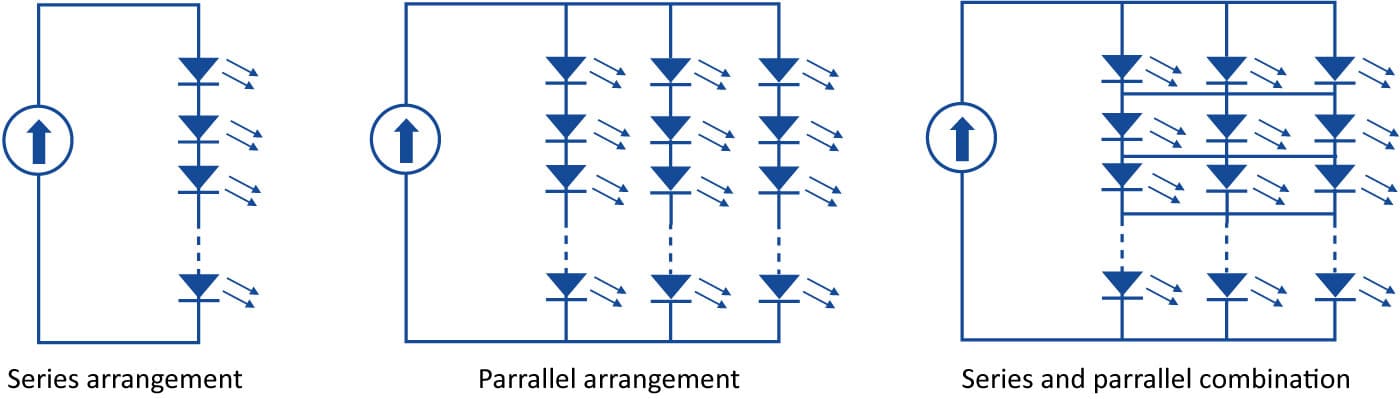

A constant current LED driver provides a fixed output current (mA), while the output voltage is within a certain range. LEDs rated to operate on constant current drivers require a specified current supply, usually measured in milliamps (mA) or amperes (A). These drivers vary the voltage along the electronic circuit, keeping the current constant throughout the LED system. The switching power supply in constant current type is actually based on the constant voltage source, and the sampling resistor is added to the output circuit internally. The circuit ensures that the voltage drop on the sampling resistor remains unchanged to achieve constant current output. A higher current rating does make the LED brighter, but without regulation the LED will draw more current than the rated current. Thermal runaway refers to excessive current exceeding the maximum driving current of the LED, which will lead to a significant reduction in the life of the LED and premature burnout due to elevated temperature. LED is a nonlinear element with negative temperature coefficient. The so-called “negative temperature coefficient” means that the internal resistance of the LED decreases as the temperature rises. And “non-linearity” will make the internal resistance decrease in a geometric progression. If it is not handled properly, it will easily cause premature aging of LEDs or even breakdown and burnout. A constant current driver is the best way to drive high power LEDs because it maintains consistent brightness across all LEDs in series.

What is a constant voltage LED driver?

Constant voltage drivers are designed for a single DC output voltage. A constant voltage LED driver is the power supply with a most common power supplies in 12VDC or 24VDC. LEDs are current devices (constant current devices with a forward voltage drop), and cannot be directly powered by a constant voltage source. When using a voltage source for power supply, the voltage source must be changed to a current source in advance. The current commonly used method is to add a current-limiting resistor to the module of LED chips. The current-limiting effect depends on the ratio of the voltage divided by the current-limiting resistor in the voltage source. The larger the ratio, the better the constant current effect and the more stable the LED current, but the greater the power wasted by the current limiting resistor, the power consumed by LED lamps will increase significantly. For these LED devices with a built-in current limiter or voltage regulator, the voltage is fixed, while the current provided by the constant voltage driver may vary. For example, in different working modes of cameras for smart city, the working current is different, but the voltage is always the same.

Advantages of using a constant current LED driver

When you are building your own fixtures or using our high power LEDs, it is in your best interest to use a constant current driver because:

- To prevent thermal runaway, which makes the maximum output current of LED driver not exceed the rated current of LEDs. ( Click here to see the LED Driver. )

- For the designer, they are easier to design the layout of LED module and help to create lights with more consistent brightness.

- Due to its characteristics, it is more suitable as a power source for street lights, flood lights, stadium lights, industrial lights, etc.

Advantages of using constant voltage LED drivers

Use constant voltage LED drivers only when using LEDs or arrays of a specific voltage because:

- Constant pressure technology is more familiar to design and installation engineers.

- The cost of these systems can be lower, especially in large-scale applications.

- Due to its characteristics, it is more suitable for these applications include simple light strips or more sophisticated distributed architectures where the current is regulated downstream at the LEDs. Such as indoor lamps, variable power equipment – such as cameras for smart lighting.

Dimming functions to be considered when selecting LED driver

0-10V dimming of LED driver

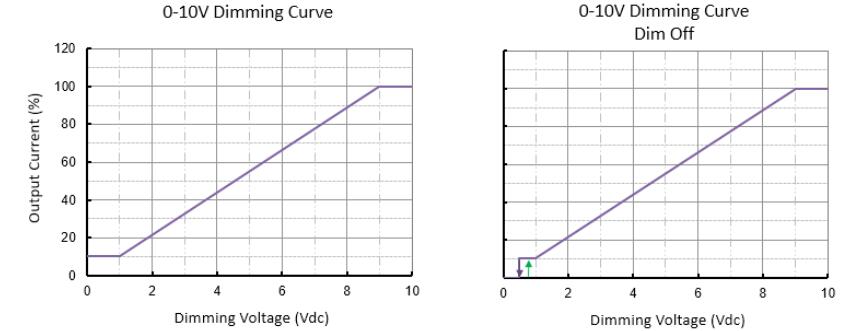

What is 0-10V dimming? 0-10V dimming is a widely used lighting control protocol and the first electronic lighting control signal system. When your power supply supports 0-10v dimming lighting control, after the power supply receives a direct current voltage (DC) between 0 and 10 volts, the LED driver can provide different output currents to drive LED chips which finally get different intensities of light for the lamps. 0-10V dimming is the simplest lighting control system, providing smooth operation and dimming to 10%, or even 1% brightness. And it can also turn off the LED light when necessory.

Dali dimming of LED driver

DALI is an acronym for “Digital Addressable Lighting Interface”. It is a digital communication protocol for the management of lighting control networks in building automation engineering. DALI is a trademarked standard used worldwide. It makes it easy to interface LED devices from different manufacturers. The equipment can include dimmable ballasts, receiver and relay modules, power supplies, dimmers/controllers, and more. The DALI system allows the control system to communicate bidirectionally with each LED driver and LED ballast/device group, that is, you can control the lamps and at the same time get the working status information feedback by the lamps. The 0-10V control is different, it only lets LED driver (controller) to control lamp in one direction. Additionally, the DALI protocol provided the communication channel they needed to control architectural lighting which is also extensible. This could be used for both simple and complex installations.

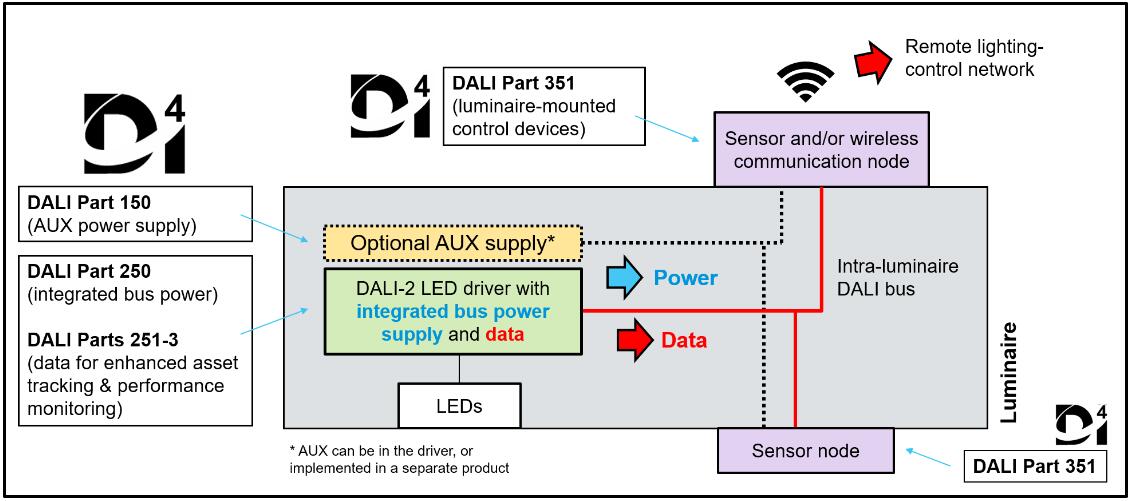

D4i refers to LED driver

D4i is an extension of the DALI-2 certification program. The D4i LED driver has an additional set of power outputs that are associated with the smart control and data monitoring. D4i is a standardized interface between LED drivers and IoT nodes or sensors. D4i drivers make it easy to change sensors on different IoT nodes or fixtures. D4i-certified LED drivers or other devices must implement the DALI standard, governing the following areas of operation:

- DALI Part 250 – integrated bus power supply

- DALI Part 251 – luminaire information used for lighting asset management

- DALI Part 252 – energy reporting

- DALI Part 253 – diagnostic data used in the servicing of lighting equipment and for predictive maintenance

- DALI Part 150 – an additional and optional standard for the provision of a 24V auxiliary power supply for smart control

- DALI Part 351 – a new specification for control devices that are used in or on, or are attached to, a luminaire.

To enable these functions, the D4i standard also sets standard protocols for data exchange between luminaire components or between luminaires and external controllers. Because D4i technology is an industry standard, each D4i-certified component is guaranteed to interoperate with other D4i-certified components.

Source: https://www.dali-alliance.org

Other functions to be considered when selecting LED driver

Timer

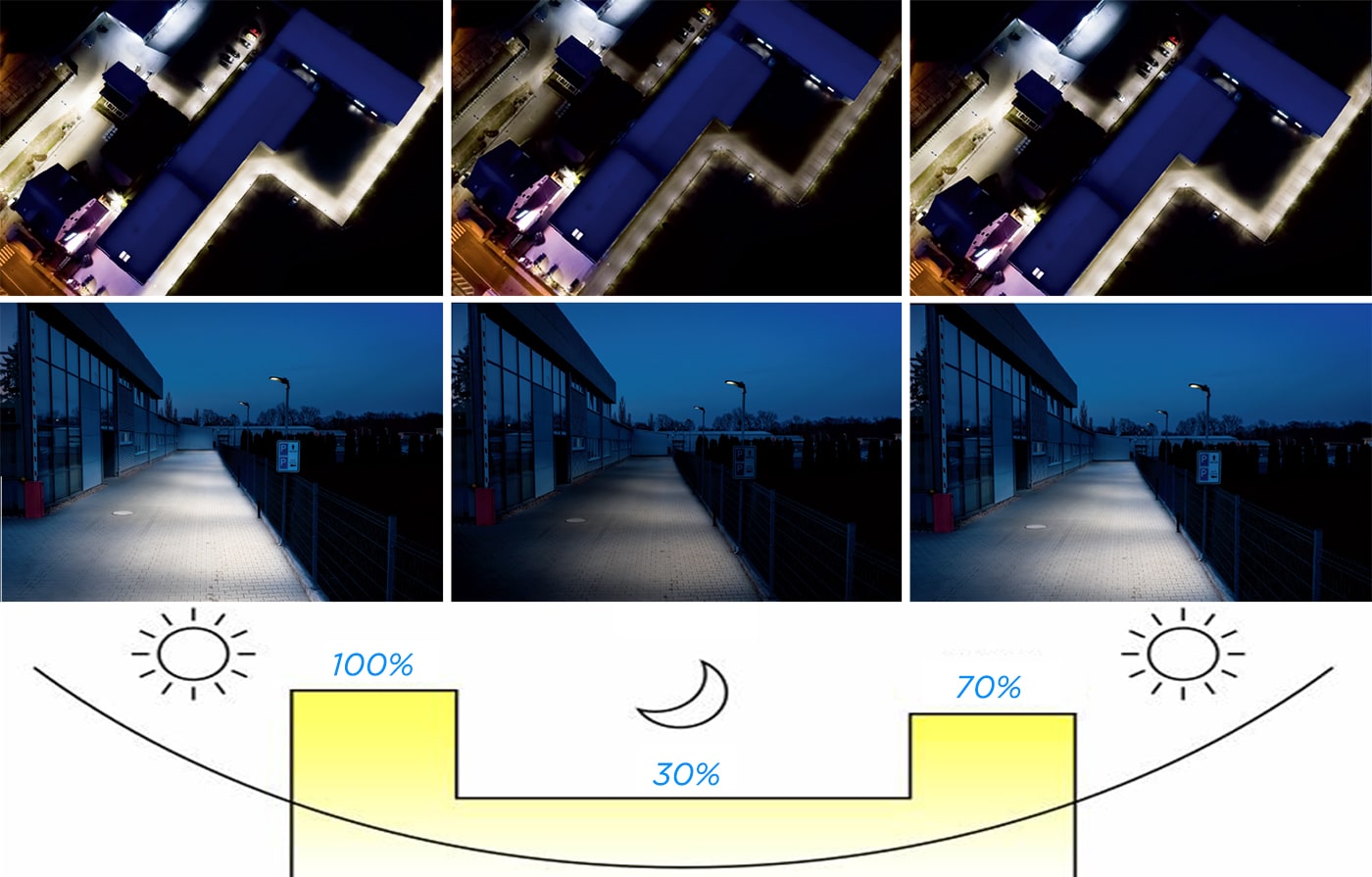

Timer dimming is a common dimming function for road lighting, which can change the output of LED street lights at night. The idea behind the time control strategy is that from late at night until early in the morning, traffic is low, so it is possible to reduce lux levels. By dimming the street light, we can save valuable energy and get evenly and reasonable lights on the entire street.

Time based, the traditional LED driver has a preset program. For example, we set up the LED driver as follows, 100% for 3 hours, 30% for 7 hours, then back to 70% for 3 hours. The lights are turned on at 18:00 and turned off at 6:00, the brightness is 100% from 18:00 to 21:00, and the brightness is 30% from 21:00 to 4:00. And it will be with 70% output at 4:00 to 7:00. The lighting result will be similar to the image below.

Astro-based or virtual midnight: Due to the different switching times of lamps and lanterns in different seasons, if the time based solution is still adopted, it does not meet the actual lighting needs. Through the Astro or virtual midnight solution, the power supply will reasonably set the time dimming curve according to the time of sunrise (light) and sunset (turn on the light) to better adapt to the lighting requirements of different seasons.

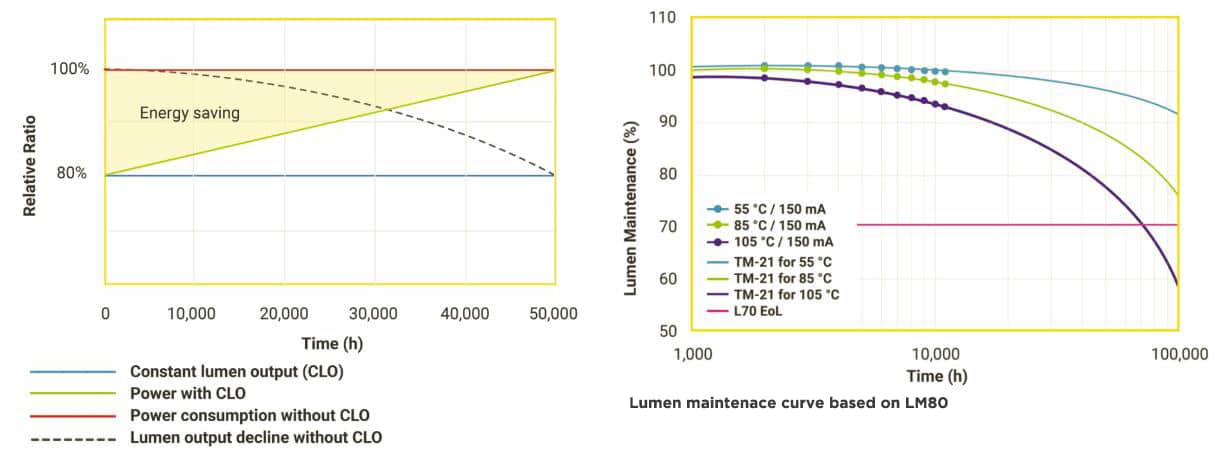

OLC

The light output of an LED module slowly decreases over its lifetime, which means that the maximum brightness of the LED when it is new installed is higher than the brightness after the luminaire has been operated for 10k or 100k hours. While the input current remains constant, the lumen output of an LED module deteriorates over time, resulting in a reduction in the amount of light at the same wattage. The main reasons for this phenomenon are the lumen attenuation of the LED chips, the pollution of the lens, and the reduction of power supply efficiency. CLO (Constant Lumen Output) overcomes this limitation. The power supply can drive the chips with a lower current during the initial period of lamp operation, and then slowly increase the current output to offset the reduction in lumen output. With the CLO solution, not only stable lighting is guaranteed, but also energy is saved, and finally the lifespan of the LEDs is increased.

To achieve a constant light output from the module, the LED driver stores the operating hours of the LED module, powers the LEDs below the maximum rated lumen output, and then increases the output current over time to counteract the decrease in lumen output. Through the curve in the figure below, you can understand the CLO function and its benefits more intuitively.

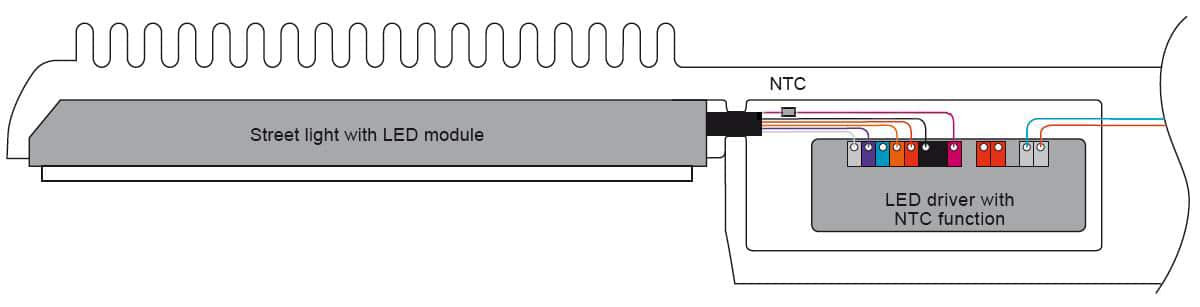

NTC

Heat dissipation has always been one of the technical bottlenecks in the LED industry. At present, we will use an aluminum heat sink (multi-rib) to dissipate heat to ensure that the LED chips will not overheat. If the LED works abnormally or the ambient temperature suddenly rises and the LED lamps fail to dissipate heat in time, this will cause the LED light source to attenuate due to overheating and affect the life of the lamps. NTC thermistors for LED street light are thermistor elements whose resistance value decreases rapidly as the temperature increases. Due to this characteristic, they are used as temperature protection devices to protect the circuit from overheating as well as temperature sensors. When the temperature is too high, the power supply can detect that the resistance is very small, and then give a 0-10V dimming signal to automatically reduce the output current which cools the LED lamp. When the temperature rises to the limit set value, the LED power supply is automatically turned off. When the temperature drops, the light is turned on again. The following is a schematic diagram of the street lamp with NTC.

ZGSM lighting solution with different LED driver

Since its establishment in 2005, ZGSM has been using high-quality LED drivers for the production of lamps. Most of ZGSM’s LED lamps use constant current LED driver, and we have good cooperation with LED driver suppliers. At the same time, ZGSM is also committed to the development of LED lamps that can achieve different dimming functions. Below we list LED drivers used by us and solutions for LED street light with different dimming functions.

Summary

This article mainly introduces the classification of LED drivers (Constant Current LED Drivers vs. Constant Voltage LED Drivers), including the definitions of the two types of drivers, their applications, advantages and disadvantages, etc. At the same time, we also introduced the common dimming function of LED power supply, mainly because this is a trend of lighting. Finally, we also introduced the functions of Timer, OLC and NTC, as well as the corresponding solutions of ZGSM. I hope everyone has a deeper understanding of LED power supplies, so that they can be applied to future designs or projects. Get in touch with us for more details.

Rated Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483