How Long do Led Lights Last ?

How Long do Led Lights Last ?

Introduction

One main advantage of LED light is its long lifespan. This is based on the fact during the usage of LED lights during the last decades. Therefore LED lights are known for their long lifespan, and many manufacturers directly print the expected lifespan on the packaging. The LED Light Lifetime is expected to range from 5 to 20 years, but the actual lifespan of LEDs is far beyond manufacturers’ simple estimates. Many factors can affect the actual lifespan of LEDs, including high heat, high frequency of use, and operating LED lights at higher than expected currents. So, how long can LED lights last?

The actual situation is that the lifespan of LED lights is usually around 4 to 6 years. For example, LED lights can last for 10 years, but if used frequently outdoors in extreme heat, they may only last for 8 years; If the lamp is placed at room temperature and rarely used, it may last for 12 years. However, it should also be noted that even if the LED lamp ( Explore different types of street LED lamps. ) does reach the manufacturer’s claimed lifespan, the lamp will experience light decay, which will reduce the light output of the LED over time.

We here will explain this based on lumen maintenance of LEDs over time and its lifetime when it’s applied in LED products. LM-80 report includes the lumen maintenance information of LEDs, while the TM-21 can be used to calculate the lifetime of the LED light. Besides, now LxxByy report of LEDs is also used for tenders, which is about the lifetime of LEDs as well. So we will you know the details about LM-80, TM-21, and LxxByy reports in this article.

What’s LM-80 and what’s it used for?

LM-80 report is the lumen maintenance test report of the LED device (LED Package, Array/Module, or COB) issued by the laboratory according to the IES LM-80 test method and standard. The LM-80 report can be used for energy efficiency certification of end products, such as ENERGY STAR certification and DLC certification for the Americas market.

In this report, the LED devices will be tested at one current and at least three temperatures (55, 85, and optional). And the test will be done at least 6,000 hours, therefore test time, LED temperature, and LED current are three main factors that we should consider in the LM-80 test.

LM-80 test method

LM-80 test should last for at least 6000 hours and it should be carried in three different temperatures and different drive currents of LEDs if needed. Therefore the three main factors refer to in the LM-80 test are time, temperature, and LED drive current.

1. Test time requirement (related to prediction accuracy)

The LM-80 test should be carried out for at least 6,000 hours and the recommended time is 10,000 hours. By this, you will obtain the LED light attenuation information every 1,000 hours. The shorter the interval time is, the more the accuracy of the prediction time is.

2. Test temperature control

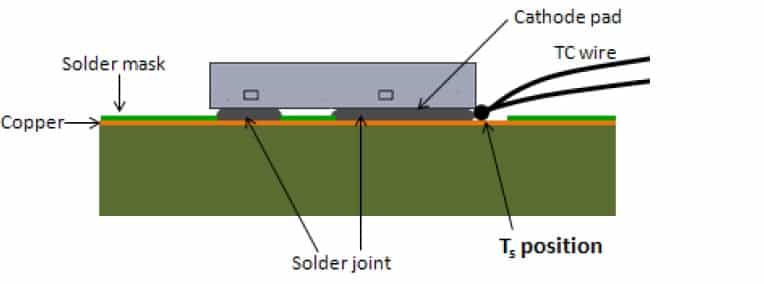

The LEDs will be tested in three groups, and the temperature at the Ts point of each group was different. Normally 55℃ and 85℃ are mandatory, while another temperature is optional. For example, Lumileds choose 105℃ as their 3rd temperature.

- During the process, the standard allowable temperature tolerance is -2°C.

- During the test, the ambient temperature of Tair near the sample must be monitored. And it cannot be lower than Ts by more than 5°C.

The Ts of each sample should be monitored in real-time during the test. Below is the Ts point for your reference.

3. LED drive current

Normally the higher the drive current, the higher the luminous flux attenuation will be. Because the LED drive current of LED light is based on the manufacturer’s design. Some will be with high drive current to get high wattage with the same quantity of LEDs as others, while others want to use low drive current to power the LEDs so the efficacy of LED light is much higher. Then we should consider the LED drive current when we are doing the LM-80 test.

After every 1000 hours of the test period, the photometric test needs to be carried out under the condition of 25℃±2℃.

LM-80 test result and report

We will get photometric test results after every 1000 hours test period. The photometric test results include meaning, median, standard deviation, maximum, and minimum of normalized flux at each temperature and each sample from the initial for every 1000 hours. And chromaticity shift reported over the measurement time should also be included.

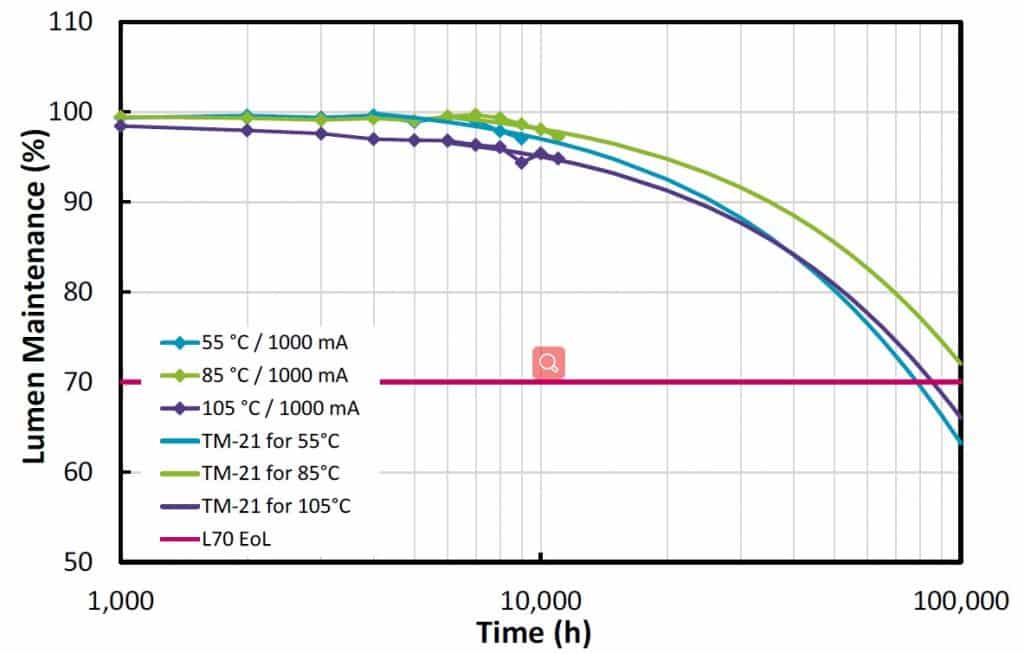

After getting the test results, we calculate the 70% lumen maintenance rate at every temperature experiment over time under ENERGY STAR standard, According to the formula, the equation is y=mx+b, B=exp(b), a=-m. Use Exponential Least Squares Curve-Fit to get Slope m and Intercept b, when calculating m and b. Below is the curve and this can also be achieved when we put the time, temperature, and lumen maintenance result into the TM-21 table.

What should a qualified LM-80 include?

What is TM-21?

How to calculate the lifetime of LED light? It’s the life estimation method mainly used for LED packaging products at present. The finished LED light can claim its lifetime L70* according to this method.

*L70 is the time when the lumen output of LED light retains 70% of its initial lumen output.

In other words, LED light rated L70 > 50,000 hours, then would retain 70% of its light output after 50,000 hours. Whereas a LED light rated L70>100,000 hours, will retain 70% of its output after 100,000 hours. Then we will say that the lifetime of this LED light is over 100,000hrs. Because when the lumen output is under 70% of the initial flux, we think it’s time to replace it with a new one.

When the LED device is applied to the finished LED light, the temperature of its corresponding point(Ts) and the drive current of LEDs are tested.

By comparing the temperature and current of LED light with the one in the LM-80 report, the data in LM-80 can be adopted if the conditions in the LM80 report are more severe. And we can download the TM-21 table at: www.energystar.gov. And this form should be used in conjunction with the LM-80.

Take our Rifle series LED Street Light 100W as an example.

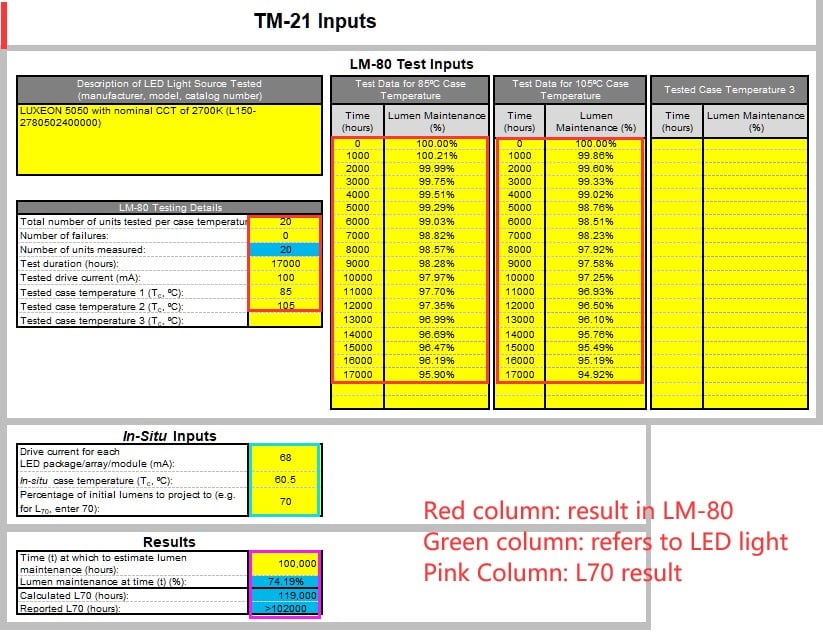

- We need to put the LM80 result(red column) into the TM21 table. We will get the TM21 table 1 at 60mA and 70℃&85℃&105℃, TM21 table 2 at 100mA and 85℃&105℃, and TM21 table 3 at 200mA and 85℃&105℃.

- Ts of ZGSM-ST17-100M is 60.5℃ and the LED drive current is 68, then we can fill TM21 table 2 with this information. Because the Ts and drive current of table 2 are more severe than these of ZGSM-ST17-100M.

- We can get the lumen maintenance rate in the pink column.

The results are as follows.

- After 100000 hours, the lumen maintenance rate is 74.19%.

- We can claim that our Rifle series has L70>102,000hrs.

But if the Ts is 90℃, while others are all same, then the result will be different. Because the result is based on curves both at 85℃ and curves at 105℃.

What does LxxByy mean?

Normally it’s expressed by an ‘Lxx Byy @ zz,000 hours’ rating, which defines the rate at which luminous flux depreciates over time. The xx digits refer to the amount of maintenance luminous flux, which is simply 100% minus the ratio of initial flux that has depreciated. The yy digits refer to the ratio of LEDs within the total quantity that would not meet the xx target maintenance flux. So, a LED with a lumen maintenance specification of L90 B10 @ 80,000 hours refers to 10% depreciation (i.e. 90% maintenance) of flux over that 80,000 hours and clarifies that at least 90% of those LEDs would achieve that 90% or greater maintenance flux (i.e. 10% of total LEDs would depreciate by more than 10%). Lumen maintenance specifications must be derived by the industry-standard TM-21 projection method, which uses data from long-term LED testing (LM-80 report, with a minimum of 6,000 hours testing) and in-situ luminaire temperature testing.

Summary

LM-80 report includes the lumen maintenance information of LEDs. The LEDs will be tested at different drive currents of LEDs, at 3 different temperatures, every 1000 hours. We will get the lumen maintenance information of LEDs at xxxmA, at yyy hours, at zzz ℃. This is about the lifetime of LEDs.

TM-21 report is used to calculate the lifetime of the LED light. When the LEDs are used on lamps, the lifetime of LED lights is partly determined by the lifetime of LEDs. How to get the lifetime of LED light? We have to put the LM80 result(lumen maintenance information) into the TM21 table. Because the main factors regarding lumen maintenance are LED drive current and temperature. So we should put Ts and drive current of LED light into right TM21 table. And TM21 table will automatically compare the Ts of LED lights and drive currents of LED lights with the one in the LM80- report. And finally, we can get the lifetime (L70) of the LED light.

LxxByy report differs from the LM80 report and TM-21 report. But it’s also regarding the lifetime of LEDs. And it’s becoming more and more common in tenders’ requirements.

We can see that these three reports LM80, TM21 and LxxByy are all related to the life of LEDs, and the lifetime of LED lamps is mainly related to temperature and drive current. Therefore, for our products including LED street lights, flood lights, high bay lights and gas station lights, we have strict requirements on the temperature of the lamps and the drive current of the LEDs, so as to prolong the service life of the LED lamps as much as possible.

Rated Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, roadway light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483