Light output of LED solution and its degradation – 62717 and LM80

Light output of LED solution and its degradation – 62717 and LM80

Introduction

Lumen output is a measurement of the total quantity of visible light emitted by a light source. It’s also commonly known as brightness or light output. LED technology typically produces more lumens than other solutions because of its high efficacy to transform electricity to light. At the same time one of the biggest advantages of LED lamps is long life, which can usually reach more than 100,000 hours (ie L70>100,000hrs). A lot of people are not familiar with this concept and how we got the 100,000 hours lifespan. Therefore, it is necessary to study relevant test standards, test methods, and result statistics so that we can deepen our understanding of light output and its depreciation which refers to lifetime of LED solution.

Why we shall pay attention to light output degradation?

LED projects have clear requirements on the parameters of lamps, such as wattage, luminous intensity distribution, peak intensity value, beam angle value, color temperature, CRI, CCT, lifespan (switching, lumen maintenance). So how to prove that your lamps meet the requirements in all aspects? IEC has formulated corresponding standards for these parameters, namely the IEC62717 and IEC62722 standards. In addition, there is also the LM-80-08 standard which refers to lifetime, which mainly tests the LED chips. In addition to the lifespan, this article does not explain too much about other aspects of the two IEC standards. In most cases, the life of the LED module is much longer than the actual test time, so many results are projected based on testing, such as the life of the LED chips is obtained according to the results of LM-80-08 combined with the TM21 table. However, the maximum test time set by IEC62717 and IEC62722 is 6000 hours, and the test object is LED modules or whole lamps. The standard does not involve the specific method of life verification, but the calculation steps are similar after we refer to related articles.

Standards refer to lighting output degradation

IEC 62717 is a standard about performance requirements of LED lamps (modules) for general lighting, which is a supplement to IEC 62031 (ie, safety requirements for LED modules). IEC 62717 mainly specifies the details for marking, size, power, luminous flux, correlated color temperature, color rendering index and life of LED modules. Three types of LED modules are covered in IEC62717: LED module with integral control gear, LED module with means of control onboard, but with separate control gear (“semi-ballasted”), and LED module with complete separate control gear.

The IEC 62722-2-1:2022 standard specifies the performance requirements, test methods and conditions for LED lamps. This standard is applicable to LED lamps for general lighting purposes. The test content is basically the same as IEC62717, except that it is aimed at the whole lamp instead of the LED module.

The LM-80-08 standard specifies the measurement method for light output maintenance, which does not specify any other failure modes of the LED chips. In addition, this method only refers to LED packages, arrays and modules, and in most cases we use a single LED chips for testing. This method describes the test method for the operation of LED light sources under controlled conditions. These light sources must be operated on external auxiliary equipment, aiming at obtaining the best reference data of the light output degradation produced by LED chips during their service life. Combined with Energy star’s TM21 table, we can get the luminous flux prediction curve of LED chips after 50,000 hours or more.

How is the lifetime calculated for LED solution?

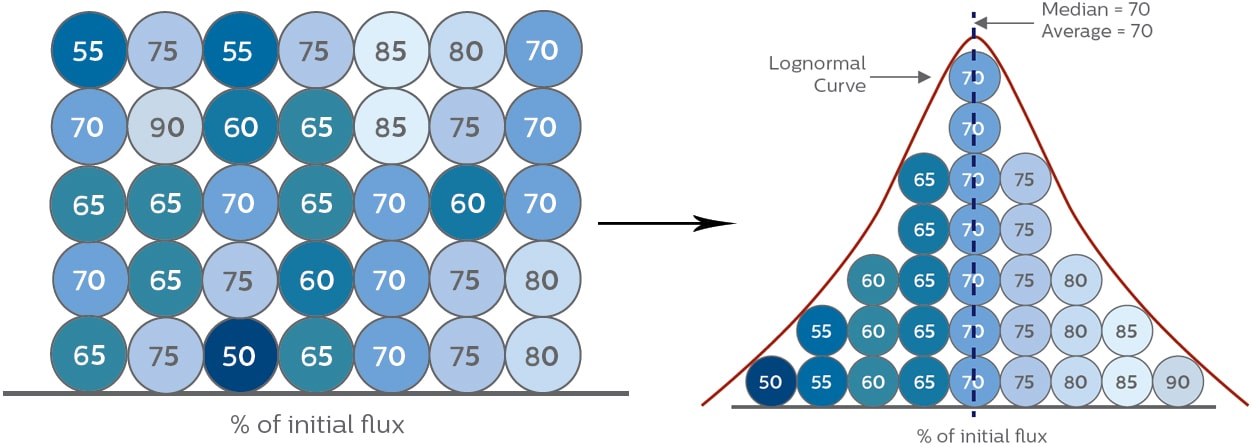

L70 is a measure of LED lifetime and is one of the most important ratings that electricians, purchasing agents, and end users can use to decide which lighting fixture is best for their projects. According to the U.S. Department of Energy, useful life (or rated life) is typically described in terms of the number of operating hours before an LED luminaire emits 70% of its initial light output, after which time the luminaire needs to be maintained or replaced to meet specified lighting requirements. By this definition, we found the L70 rating as the life definition of lamps. Intuitively, we have tested 35 pieces LED chips. After using for a period of time (assuming 50,000 hours), the luminous flux of these LEDs has different degrees of attenuation, and their luminous flux is normally distributed, as shown in the figure below. We can conclude that after 50,000 hours of use of the LED chips, 50% of the LED chips are above 70% of the initial luminous flux, and the rest are below 70%. Since it is a normal distribution, we can conclude that after 50,000 hours, the lumen of the lamp is maintained at about 70%, that is, L70>50000hrs.

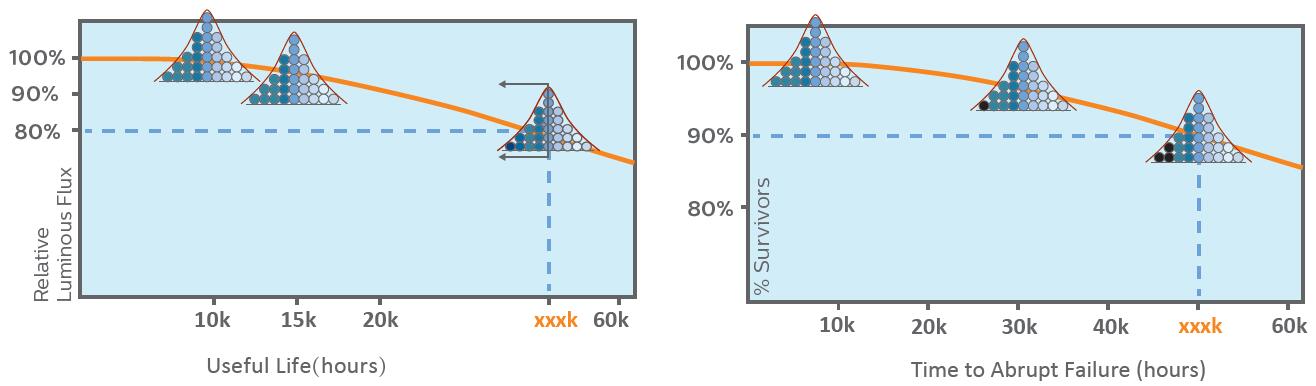

The above is a hypothetical ideal situation, because the actual life of the LED is longer than this, and the manufacturer and the laboratory do not have so much money, equipment and manpower to do such a long test. The current mainstream test time is 10000 hours, 14000 hours, or 18000 hours. Through curve fitting, we can estimate the lumen maintenance of the LED chips/modules after 50,000 hours and 10,000 hours, so we can deduce the life of the LEDs/lamp, as shown in the left figure below.

Performance requirements specified by 62717

Previously, we introduced the test content of LM80 in other article, you can check it if you are interested. The test standards of 62722 and 62717 are basically the same, except that the former is aimed at lamps, while 62717 is aimed at LED modules. As follows, we will introduce the test content of 62717 in detail. 62717 In addition to below testing content refers to the lamp life, the test content also includes wattage, Luminous intensity distribution, peak intensity value, beam angle value, color temperature, CRI and CCT, etc.

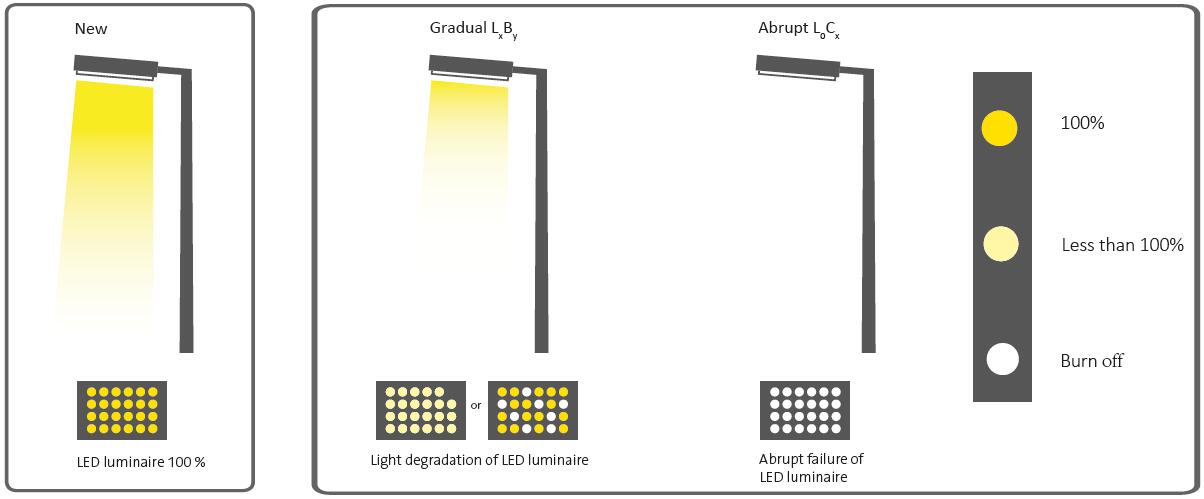

Lumen maintenance

The lifetime of an LED luminaire is not defined solely by the point of abrupt failure. Most lamps will not actually fail at all for a given period of operation, and their brightness will decrease (degrade) over time. Therefore, the lifetime of LED luminaires is basically limited by luminous flux falling below a predefined minimum level “x[%]” and sudden failure (failure of the LED power supply is not considered here). In addition to LED degradation, reduction or degradation of luminous flux may be due to failure of individual LEDs or LED modules. Depending on their design, these LEDs or LED modules may be integrated in large numbers in luminaires. The figure below shows the original state, degradation and abrupt failure of LED street lights in three cases.

The current IEC 62717 and 62722 standards define two life standards ” Gradual light output degradation ” and ” Abrupt light output failure”. On this basis, the life standard shown in the figure below is given, highlighting the current distinction between the service life (LxBy) and the median service life (Lx) (according to the definition of life calculation, we understand that Lx is actually LxB50). LED luminaires have a very long service life and failure time, so it is not possible to monitor the entire service life of LED luminaires before they are put on the market. Instead, monitoring is carried out over a shorter period of time and the service life and failure figures are extrapolated by precisely defined methods.

Gradual light output degradation{Useful Life (LxBy), Median useful life (Lx)}

Useful life is based on the percentage of luminaires/beads affected by increased luminous flux attenuation, expressed in LxBy. The allowable luminous flux attenuation of LED lamps/LED chips during their service life is represented by the variable “x”, which refers to the percentage of the rated luminous flux of the lamp. The typical value of “x” is 70% or 80% (L70 or L80), indicating the service life of the LED chips/luminaire when the ambient lighting temperature is 25°C (for example, 50,000 hours). LxBy, indicates the length of time during which y% of the same type of LED chips/lamps cannot provide at least x% of the initial luminous flux. The median service life Lx (excluding By) is actually based on the service life of By = B50. Lx also represents the length of time, that is, at this time, 50% of the same type of LED chips / lamps cannot provide at least x% of the initial luminous flux. Remember, the By standard says nothing about the luminous flux of an individual LED luminaire or its precise distribution.

Abrupt light output degradation(L0Cy)

The term Abrupt Failure Value (AFV) indicates the percentage of LED luminaires that fail suddenly before reaching the median service life Lx. LED luminaires in which only a single LED fails and LED luminaires in which only one of several LED modules fails are not classified as abrupt failures, the value of which is expressed using L0Cy. L0 means that the same type of LED chips/luminaire gives 0% of its initial light output. “Cy” indicates the percentage of LED chips/luminaires that no longer emit any light to the total. For example, L0C10 reflects the time when 10% of the LED chips/ LED chips suddenly no longer emit any light, and its failure prediction curve can be seen in the figure Gradual light output degradation and abrupt light output degradation. Relatively speaking, the abrupt failure probability of LED solutions is low, so a few buyers and projects require this parameter. In addition to the abrupt failure of the LED chips, there is also the abrupt failure of the whole lamp, which involves the reliability of the LED system.

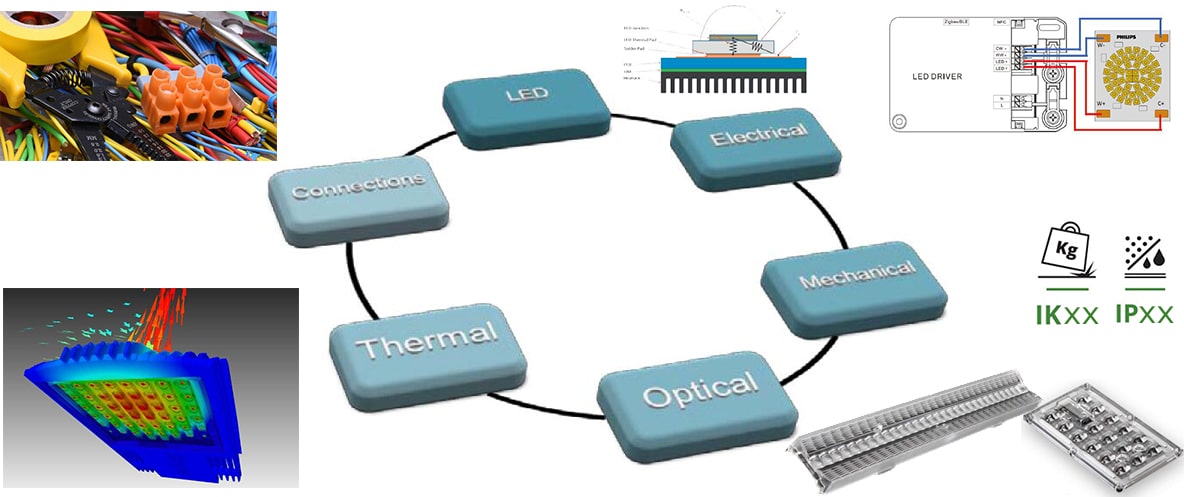

System Reliability – The life expectancy of an LED luminaire is affected by the reliability of all the components used in the system as well as the environmental conditions where the luminaire will be used. Failure of one luminaire component can lead to abrupt failure of the entire luminaire. There are many component-based factors that affect the reliability of LED lighting systems, such as power quality, use environment, structural protection level, LED connection quality, etc.

Endurance test

Temperature cycling Measurement (Alternative test 1 or 2 with 1 K/min)

For example, the LED module of test 2 is placed in a test chamber in which the temperature is varied from ‒10 °C to +50 °C over a 4 h period and for a test duration of 250 periods (1 000 h). And the LED module is mounted on an appropriate heat sink to reach its maximum rated tp temperature at +50°C test chamber temperature.

A 4 h period consists of 1 h holding on each extreme temperature and 1 h transfer time (1K/min) between the temperature extremes. The LED street light is switched on and off for 17 min.

Supply switching test

At the test voltage, current or power, the LED module should be switched on and off for 30 seconds each. The number of repeated cycles (50,000) is equal to half the median rated service life Lx in hours. Example: If the rated median service life is 100,000 hours, then the number of cycles is 50,000).

Accelerated operation life test

The LED module should work continuously without switching at the test voltage and the temperature 10K higher than the rated maximum recommended working temperature, and the working time is 1000h. Any thermal protection that would shut down the LED module or reduce light output should be bypassed, such as over temperature protection built into the LED power supply.

ZGSM solution with 62717 and 62722

ZGSM can provide various reports for verifying the parameters and lifetime of lamp including LM80, TM21, ISTMT, LM79, IEC62717 and IEC62722, etc. Below we list different ZGSM street lamps, and those certificates and reports which is issused by third party.

Summary

Through this article, we hope that everyone has a certain understanding of the light output degradation of LED solution and the corresponding useful life. We also have graphic explanations on how to predict the service life of lamps, hoping that everyone can better understand the principle of life prediction. We can see that for LED chips, the corresponding standards are LM-80-08 and IEC62717. For LED lamps(such as street and flood lights), the corresponding standard is IEC62722. For the life of LED solution, its main basis is to test its lumen maintenance rate, all three standards are involved, and it is mainly aimed at gradual light output degradation. IEC62717 and IEC62722 also stipulate the abrupt light output degradation, as well as the durability test of LED chips and lamps. In addition, the structural design of an LED luminaire has a significant impact on its performance and declared lifetime, and we need to understand the causes of luminous flux degradation and abrupt failure (including electrical and thermal operating specifications of the LED module, ambient temperature in which the luminaire is used, and other luminaire environments). The project party’s understanding of these can also help it better choose suitable lamps, and it is also helpful to formulate a maintenance plan for its lighting project.

Rated Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483