Lighting power density – why is it so important?

Lighting power density – why is it so important?

Introduction

As a lighting practitioner, the concept of Lighting Power Density (LPD) should not be unfamiliar. In many projects, especially those aimed at participating in green building or LEED award selection of public buildings, as well as the pursuit of ultra-low energy consumption of building projects, the lighting power density often has more stringent requirements. However, due to the nature of the lighting industry, the relative prominence of the manufacturing segment has led to a tendency for the industry to focus more on the product itself, such as the optical properties of the materials or the product-related specification standards, while the specification of the application end, especially the electrical-related power density concept, may not be sufficiently emphasized. This tendency may lead to a lack of understanding or familiarity with lighting power density within the industry. The purpose of this paper is to provide an in-depth explanation of the definition, calculation and importance of lighting power density, and to discuss how to ensure that LPD meets the appropriate requirements in specific application scenarios, such as street lighting, industrial lighting and stadium lighting (Check to see ZGSM sports lighting soutions ).

Concept and calculation formula of LPD

Lighting power density is the power rating of general lighting per unit area. It represents the load of any lighting device in any defined area, or the wattage per square meter/foot of the lighting device. These watts include the consumption of light sources, ballasts, LED power supplies ( What’s LED power supplies? ) or transformers, etc. However, in the lighting industry, it is usually associated with the Lighting Power Allowance (LPA) allowed by the relevant building energy codes. Where the lighting requirements are met and the LPD is below the lighting power allowance, the smaller the value the better. LPD = P/S in watts per square meter (W/m). Assuming that the area of a room is 10 square meters and the total power of the lighting equipment is 100 W, then LPD = 100W/10m2 = 10W/m2.

Why LPD is important in lighting?

Compliance with energy-efficiency standards: Many countries and regions around the world have set strict energy-efficiency standards, such as the ASHRAE 90.1 standard in the United States and the Architectural Lighting Design Standard in China. They have clear requirements on LPD. Since LPD directly reflects the lighting power per unit area, strict control of this indicator can effectively reduce the power consumed by lighting, thus reducing the overall energy consumption of the building to reduce carbon emissions.

Promote the development of the industry: LPD constraints have prompted lighting product manufacturers to actively seek technological breakthroughs, continuously improve the luminous efficacy of LED products and optimize product spectra, in order to provide better lighting effects while meeting LPD requirements. At the same time, lighting designers can also select products and optimize lighting simulations ( ZGSM offer lighting simulation for most cases ) according to the requirements. All of this contributes to the conscientious development of the industry and enables consumers to enjoy better products and services.

Building certification and cost control: In green building certification (e.g. LEED, BREEAM), LPD is an important indicator for evaluating a building’s energy efficiency. Optimizing LPD can help projects achieve higher certification levels. In addition, the lower LPD of the lighting scheme used in a building often means that the building needs fewer luminaires (although the cost of individual luminaires can sometimes be on the high side) and a smaller distribution system, thus reducing the initial investment cost of the project, reducing the cost of power consumption at a later stage, and maximizing cost control and efficiency in the long term.

LPD requirements for different applications

LPA in street lighting

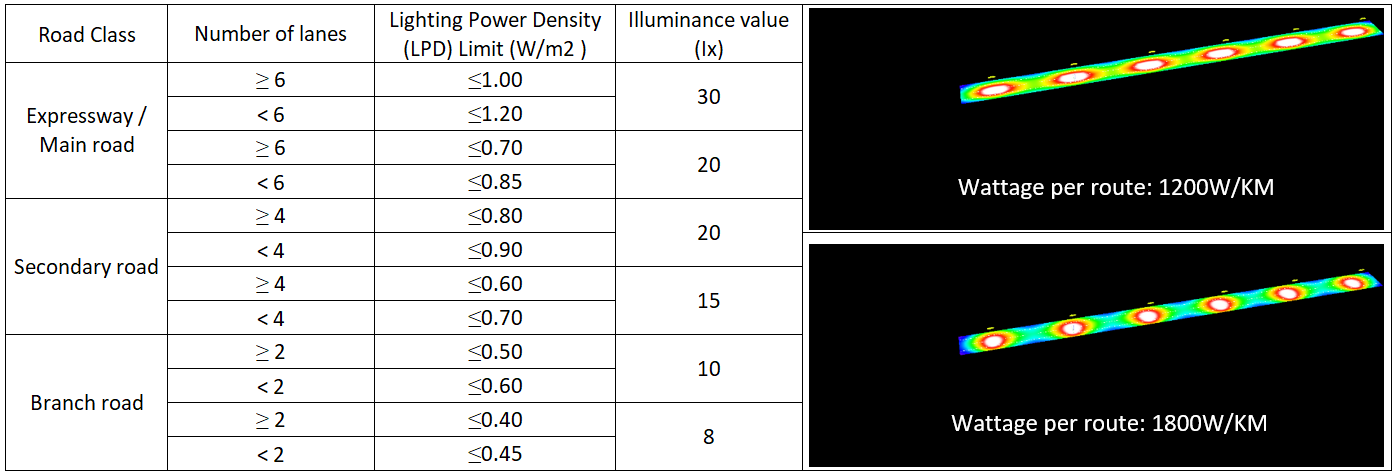

ASHRAE 90.1-2019, the ” Energy Standard for Sites and Buildings Except Low-Rise Residential Buildings”, has many requirements for LPD. However, after checking this standard, no LPD requirements for road lighting were found, only LPD requirements for parking lots and driveways in parking lots ( More about parking lot lighting ). In China’s CJJ 45-2015 “Urban Road Lighting Design Standard”, there are LPD requirements for road lighting. It makes the following provisions for LPD based on the number of lanes and lighting requirements (illuminance). Of course, in practical applications, the lower the LPD value, the better, so that the product is more competitive.

Below we list two lighting simulations. The results show that in order to achieve a brightness of 1cd/m2, with a pole spacing of 33 meters, the former requires 1800W/KM for a 60W street lamp, while the latter only requires 1200W/KM for a 40W street lamp ( ZGSM Rifle series 40W streetlight ). Although both lenses are T2M, there are still some differences in their light distribution. The latter has a larger vertical light distribution angle and a smaller lateral light distribution angle ( What’s lateral light distribution? ), so it is more suitable for roads with a road width smaller than the installation height and a smaller pole spacing (the road width in the simulation is 7.0 meters, with 2-meter-wide sidewalks on both sides, and the installation height of the lamp is 9 meters).

LPA requirement in sports lighting

According to the ASHRAE 90.1-2019 standard, only the lighting power density (LPD) of sports arenas is required (LPD < 0.73 W/ft²). However, referring to FIFA light standard C (Eh > 1250 lux), we can find that it is difficult to meet this standard according to the ASHRAE LPD requirements. By simplifying the calculation, Eh = light efficacy × LPD = 160 lm/W × 0.73 W/ft² = 1280 lux. However, in actual applications, the maintenance factor (usually 0.7-0.8) and stray light will significantly reduce the effective illuminance. Therefore, even if higher-efficiency lamps are used or more reasonable lighting simulations are performed, the actual illuminance may not reach 1250 lux. In JGJ153-2016 “Sports Lighting Design and Testing Standards”, the lighting power density limits for stadium lighting ( View LED outdoor stadium lighting supplier ) are detailed. The standard specifies LPD according to the type of venue, height and competition level ( Competition level vs sports lighting price ), and provides LPD requirements for outdoor training grounds (as shown in the table below). The standard believes that the lighting power density value should be determined according to the ratio of the total installed power of the lamps to the area of the competition venue under the lighting level corresponding to different sports. The value should comply with the provisions in the table, but the lighting power density limit should not be used as the basis for lighting design. In practical applications, calculation methods such as average illuminance and point illuminance should be used. First, calculate the illuminance, and then calculate the number of lamps used and the lighting load (including light sources, LED drivers and other auxiliary electrical equipment of lamps) on the premise of meeting the standard value of illuminance, and then use the LPD value for verification and evaluation.

| Lighting class as per JGJ153-2016 | Lighting class as per EN12193 – Tennis as example | Horizontal illuminatio (Eh, lux) | Height (m) | Lighting power density (W/m2) |

| I | III | 200 | 12≤h<20 | 4 |

| 20≤h<30 | 7 | |||

| II | II | 300 | 15≤h<20 | 7 |

| 20≤h<30 | 11 | |||

| 30≤h<50 | 14 | |||

| III | I | 500 | 20≤h<25 | 18 |

| 25≤h<35 | 21 | |||

| 35≤h<40 | 23 |

LPD in high bay lighting

For indoor lighting, ANSI/ASHRAE/IES Standard 90.1-2022 has a lot of space describing the LPD requirements for different buildings, including exercise centers, automotive facilities, fire stations, hospitals, and manufacturing facilities. The LPD requirement is between 0.17-0.92, so the total lighting power limit for different buildings can be calculated, that is, the total lighting power limit = building area × LPD limit. However, this calculation method is relatively general, because different buildings include different types and numbers of rooms, such as offices, lounges, corridors, warehouses, assembly workshops ( Find more about industry lighting - workshop), canteens, and parking lots in factories. The standard also makes different LPD requirements for different functional areas (space types). The standard recommends using the Space-by-Space Method to determine the LPD limit, that is, the total lighting power limit of the factory = ∑ (area of each space × LPD limit of the space).

| Lighting Power Density Allowances Using the Building Area Method | Space-by-Space Lighting Power Density Allowances | |||

| Building Area Type | LPD (W/ft2) | Building-Specific Space Types | LPD (W/ft2) | RCR |

| Gymnasium | 0.75 | Office ≤150 ft2 | 0.73 | 8 |

| Hospital | 0.92 | 150 ft2 < Office ≤ 300 ft2 | 0.66 | 8 |

| Office | 0.62 | Office > 300 ft2 | 0.56 | 4 |

| Warehouse | 0.45 | Manufacture falicity(High bay area) | 1.24 | 6 |

| Workshop | 0.86 | Manufacture falicity(Low bay area) | 0.85 | 3 |

In addition, Room Cavity Ratio (RCR) is also mentioned in this standard. When using the space-by-space method, the spatial LPD allowance for individual spaces is allowed to be adjusted based on the room cavity ratio (RCR). RCR is a value that characterizes the room geometry. In calculating lighting design, it is closely related to the utilization factor of the light emitted by the lamp. The smaller the room cavity ratio, the higher the light utilization factor, and the smaller the LPD (power density per unit area) value corresponding to the standard illumination; conversely, the larger the room cavity ratio, the smaller its utilization factor and the larger the LPD value. The calculation formula for room cavity ratio is RCR=2.5 x Room Cavity Height x Room Perimeter Length/Room Area. According to ASHRAE 90.1 standard, we need to consider the impact of room cavity ratio on LPD requirements. Generally speaking, when the room cavity ratio is greater than the limit, the power density is allowed to increase by 20%. When the illumination standard level is increased or decreased, the power density limit needs to be converted according to the corresponding proportion.

For example, in an ordinary office, the illumination value is required to be 500lx, the space is 10 meters long, 10 meters wide, and the lamp is installed at a height of 6 meters. What is the lighting power density limit? Let's first calculate its room cavity ratio, RCR=2.5*(6-0.75)* (10+10)*2/100=5.25. According to ASHRAE 90.1 standard, the power density limit for offices>300ft2 is 0.56W/m². If the room shape index of the space is greater than 4, the limit can be increased by 20%, and the power density limit can be taken as 0.672W/f², that is, the power density of the space needs to be less than 7.35W/m².

How to reduce LPD in your lighting project?

ZGSM clearly recognizes the importance of LPD. In practical applications, we use lighting simulation and lens selection to reduce the LPD value as much as possible. Similarly, developing and applying high-efficiency ( Benefits of high luminous efficacy ) lamps is also a very simple and feasible method.

Reasonable lighting design

In lighting simulation, the parameter LPD is often involved, so how can we make this value in the simulation as low as possible? First of all, you need to have a certain understanding of lighting simulation, be familiar with the characteristics of light distribution of lamps, and their utilization in different spaces (length, width and height). For example, in road lighting, the required illumination/brightness level should be accurately calculated according to the EN13201 lighting standard ( Standards for street lighting ) to avoid excessive lighting, thereby reducing LPD. For another example, in the stadium lighting simulation, lowering the installation height of the lamp can effectively reduce the wattage of the lamp, but this will have a certain negative impact on uniformity. Due to the complexity of the content involved, we cannot explain it in detail here. If you are interested, you can check Why sports light price differ a lot?

Reasonable light distribution

Excellent lighting designers can select lamps with appropriate light distribution curves according to the geometry and purpose of the application site to ensure uniform light distribution while avoiding light waste. In indoor lighting, we can use lamps with narrow light distribution for narrow and long spaces (such as shelves), and use lamps with wide light distribution for wide areas (such as offices). Narrow light distribution lamps can focus light on the target area (such as shelves or aisles) to reduce spill light; while wide light distribution lamps can evenly cover the entire space with light and reduce the presence of dark areas. In outdoor lighting ( Click the link to explore the top LED lighting manufacturer in China and find the perfect lighting solution for your needs! ), such as stadium lighting and road lighting, we can use asymmetric light distribution ( What's asymmetric light distribution? ) to focus light on the stadium and road, while minimizing glare and light spill. This design can not only improve lighting uniformity. What’s more important is that it can also reduce LPD of lighting solutions.

Improve the luminaire efficacy of your LED light

Improving the luminaire efficiency is an effective way to reduce LPD. Since its establishment in 2005, ZGSM has been committed to the research and development of high-efficiency LED lamps. These measures include selecting high-efficiency LED chips, using high-efficiency LED drivers (normally >0.90) to reduce power consumption, and using high-transmittance lenses and glass to reduce unnecessary light loss inside the lamp. ZGSM has made good progress in this regard. The following are ZGSM's LED street lights with different luminous efficacy ( What's luminous efficacy? ) at different times. If you are interested, check to find more details.

Summary

Lighting Power Density (LPD) is a key metric for modern lighting design that bridges the gap between energy efficiency, environmental sustainability and cost-effectiveness. In this article, we learn about the concept of LPD, how it is calculated, and its requirements in different scenarios, such as street lighting, sports lighting, and high bay lighting, which can help us make informed decisions that are relevant to real-world needs while meeting regulatory standards. Through proper lighting design, careful light distribution, and the use of high-efficiency fixtures such as ZGSM LED lamps ( More ZGSM LED lights ), we are able to achieve significant energy savings, i.e., reduce the power consumption of a lighting project without compromising the quality of the lighting. This not only enables projects to comply with regulations and minimize energy consumption, but also encourages LED luminaire manufacturers to optimize the performance of their lighting fixtures (lenses and luminous efficacy) and to provide their customers with optimized lighting simulations.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483