Safety and structural requirements of street lighting

Safety and structural requirements of street lighting

Introduction

CE certification means that the product has reached the safety requirements stipulated by the EU Directive, which mainly includes CE EMC and CE LVD. The EMC of LED lamps is an electromagnetic compatibility directive, including conducted emission and radiated emission and harmonics. The LVD of lamps is a low-voltage directive, which is specially used for electrical safety performance testing. Both EMC and LVD belong to the CE standard, and LED lighting products should comply with these two directives of CE standard. According to EU regulations, LED lamps exported to EU countries must pass CE certification, which includes the EMC and LVD directive. The EU CE certification EMC directive for LED lighting products is 2014/30/EU and its main standards are EN55015, EN61000-3-2, EN61000-3-3 and EN61547. LED lighting products EU CE certification LVD directive is 2014/35/EU, and its main test standards are EN 60598-1, EN 60598-2 series, EN 61347-1, EN 61347-2-13, EN 62031 and EN 62471 etc. Beside this, structure of the LED lighting also should be considered. Becuase it matters with the lifetime, installtion and maintenance of LED products ( Learn common causes and solutions for fix street light issues in outdoor lighting systems. ). This article will mainly discuss the safety and structural requirements of street lighting.

Why we shall pay attention to the safety and structural requirements?

ZGSM focuses on the production of LED street lights, we believe that LED street lights (road lighting) play a vital role in the overall safety of drivers and pedestrians, can significantly improve the public use of outdoor spaces at night, and improve the overall quality of life in the area. From the driver’s perspective, proper road lighting can help drivers identify road patterns, environmental conditions when they are approaching streets, intersections, landmarks, pedestrians, wildlife, and other vehicles, thereby minimizing collisions, injuries, and even fatalities. At the same time, pedestrians and the general public also benefit greatly from high-quality road lighting. Pedestrian crossing areas ( Standard and requirements refers to pedestrian lighting ) are easier to identify with proper road lighting. Studies have also shown that people feel safer when proper road and outdoor lighting is installed.

Because of the role of LED street lights in public safety, our point of view is that lighting products must meet the requirements of relevant standards and directives, including CE EMC and LVD standards. Of course, the structure of lamps must also meet the corresponding requirements. Public safety of street lighting systems is the primary responsibility of street lighting asset owners, who need to ensure that their systems are maintained and operate safely, which mitigates the risk of electric shock to the public, among other things. Fortunately, there are laboratories providing relevant testing and certification all over the world, providing a full range of product safety and performance testing and certification services to ensure that products meet relevant electromagnetic compatibility, low voltage and structure standards before they are put on the market.

Equipment covered under the EMC Directive and LVD

We list the different equipment which are covered under the electromagnetic compatibility.

| Directive | EMC | LVD |

| Equiments included | An electrical or electronic product | Electrical appliances |

| Lighting equipment | ||

| Electrical cables | ||

| Power Supply Units | ||

| Equiments excluded | Quartz watches | Electrical equipment for use in an explosive atmosphere |

| Cables | Electrical equipment for radiology and medical use | |

| Passive antennas | Electrical parts for passenger lifts | |

| Corded speakers or headphones | Plugs and sockets for domestic use |

Safety requirements of LED lighting

Electromagnetic Compatibility Directive (EMC)

The lamps shall comply with the EU Electromagnetic Compatibility (EMC) Directive 2014/30/EU, and meet the EMC requirements specified in the Directive according to the standards shown in Table 2. Electromagnetic compatibility testing refers to the ability of a device or system to work normally in its electromagnetic environment without causing unacceptable electromagnetic disturbance to anything in the environment. EMC is an important indicator for evaluating product quality. EMC testing is mainly divided into: EMI (Electro-Magnetic Interference) – electromagnetic disturbance test and EMS (Electro-Magnetic Susceptibility) – electromagnetic immunity test.

EMI (Electro-Magnetic Interference) – electromagnetic disturbance test, the main test content includes Conducted Emission – conducted disturbance test and Radiated Emission – radiation disturbance test. EMS (Electro-Magnetic Susceptibility) – electromagnetic immunity test, the main test content includes ESD – electrostatic immunity test and SURGE – surge (impact) immunity test. Compliance with EMC requirements shall be demonstrated by the manufacturer’s Declaration of Conformity (DoC) in relation to the CE marking and its technical file or by the test results of a conformity assessment body.

Table 2. EMC standards specified in the Electromagnetic Compatibility (EMC) Directive 2014/30/EU.

| Standard Number | Description | General purpose luminaires | Road and tunnel lighting | Flood lighting |

| EN/IEC 60598-1:2021 | Luminaires – Part 1: General requirements and tests | √ | √ | √ |

| EN/IEC 60598-2-1:2021 | Luminaires – Part 2-1: Particular requirements – Fixed general purpose luminaires | √ | ||

| EN 60598-2-3:2003 | Luminaires – Part 2-3: Particular requirements – Luminaires for road and street lighting | √ | ||

| EN 60598-2-5:2015 | Luminaires – Part 2-5: Particular requirements – Floodlights | √ | ||

| EN 62493:2015 | Assessment of lighting equipment related to human exposure to electromagnetic fields | √ | √ | √ |

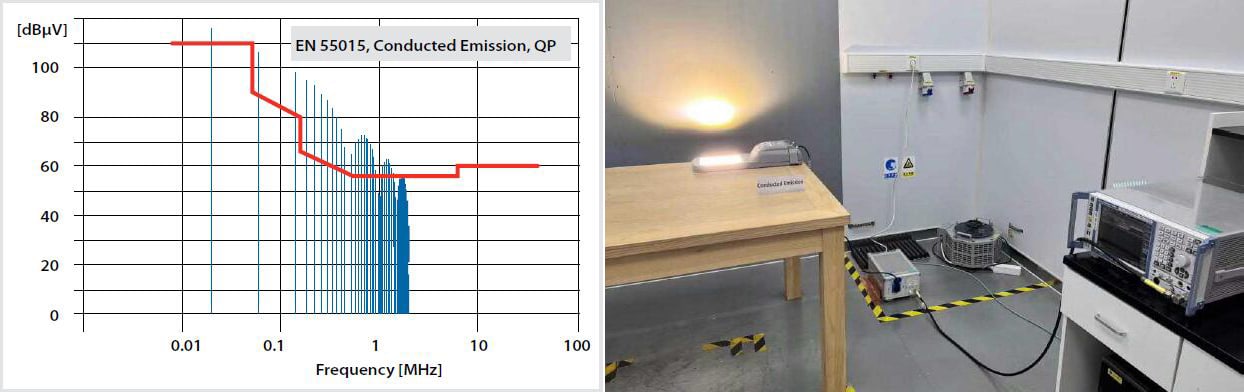

EN 55015

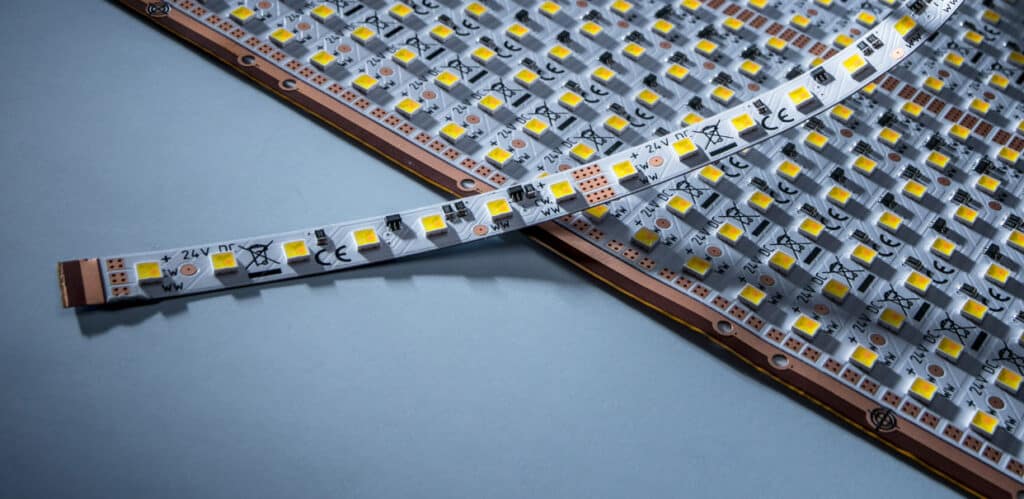

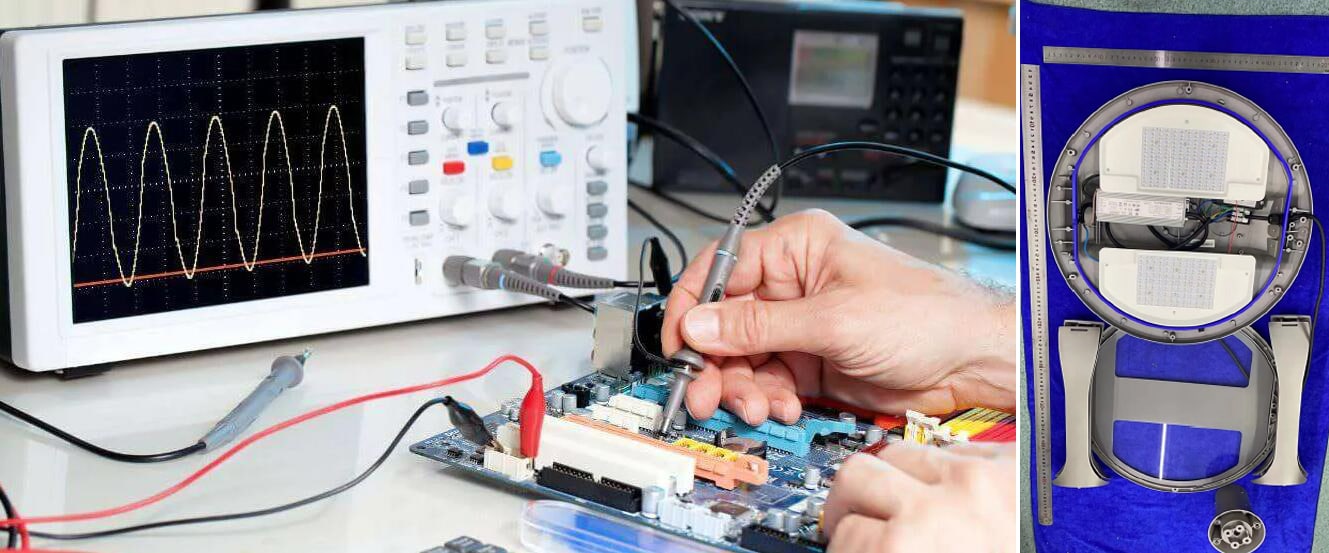

Test content according to the EN 55015 standard mainly includes conducted emission test and tadiated disturbance/emission test. The former mainly corresponds to conducted emission from 9KHz to 30MHz, while the latter mainly corresponds to radiated emission from 30MHz to 300MHz. Below is the photo of ZGSM rifle series which is under EMI testing.

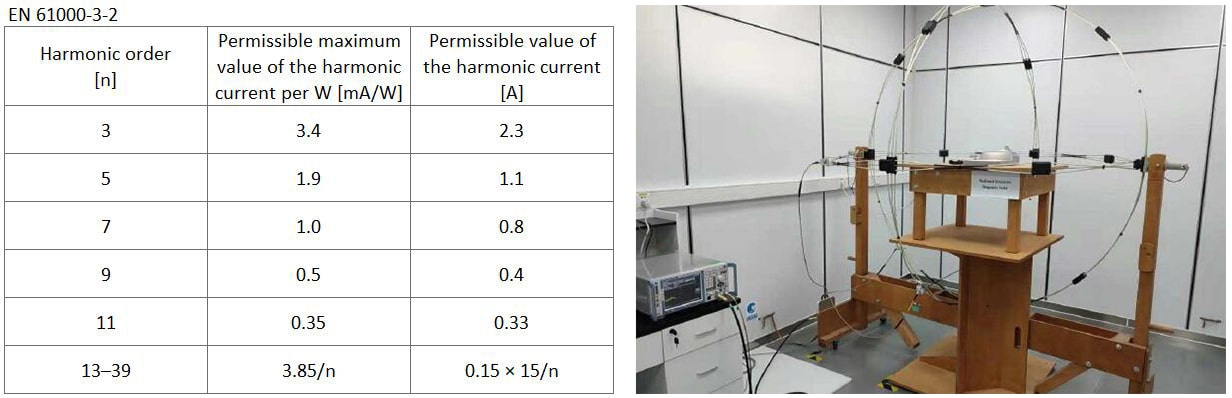

EN 61000-3-2

EN 61000-3-2 standard deals with harmonic currents caused by electrical and electronic equipment with an input current less than or equal to 16A. In addition, the equipment must be intended for connection to a public low-voltage network. The EN 61000-3-2 standard defines clear limits for harmonic currents. All electrical or electronic equipment complying with EN61000-3-2 is classified as Class A to Class D. Lighting equipment and accessories are designated as Class C. For lighting fixtures, the harmonic current emission limit varies according to the wattage. The figure below shows the harmonic limit of some wattages and ZGSM street lamp are undergoing related tests.

EN 61000-3-3

This standard describes the limit values for voltage changes and flicker per phase below 16A in low-voltage power supply systems. The new standard does not require testing for incandescent lamps below 1000W and discharge lamps and LED lamps below 600W, which are considered to meet the standard requirements. While in the old version of the standard, it is necessary to test LED lamps above 200W to determine whether they meet the standard requirements.

EN 61000-4-5

According to the requirements of the EN 61000-4-5 standard, the lightning surge test on the power line and the communication line is respectively simulated. Since the impedances of the lines are different, the waveforms of the surges on these two lines are also different, so they should be simulated separately. The surge immunity of the luminaire is at least 6kv in differential mode and at least 8kv in common mode. The test shall be carried out according to the standard EN 61000-4-5:2014, using 1.2/50µs – 8/20µs combined wave, with a source impedance of 2Ω in differential mode and 12Ω in common mode. For installations with overhead cables or high masts (HM > 20 m), the surge immunity of the luminaire shall be at least 10kv in differential mode and at least 10kv in common mode. To meet this requirement, a separate surge protection device can be used. In this case, the test shall be carried out according to the standard EN 61643-11:2013.

Low Voltage Directive (LVD)

Luminaires shall comply with the Low Voltage Directive 2014/35/EU and meet the safety requirements for luminaires specified in the directive according to the criteria stated in Table 3. The purpose of the LVD is that electrical products, when properly installed, maintained and used in accordance with their intended use, do not endanger the health and safety of humans and domestic animals, or endanger property. The Low Voltage Directive covers all risks arising from the use of electrical equipment, not only electrical, but also mechanical, chemical (especially emissions of hazardous substances), health effects of noise and vibration, necessary ergonomic requirements, and protect against the hazards specified in the directive. The fulfillment of the safety requirements of the luminaire must be accompanied by the manufacturer’s Declaration of Conformity (DoC) and its technical documentation (CE LVD certification) related to the CE mark.

Table 3. Safety standards specified in the Low Voltage Directive 2014/35/EU.

| Standard Number | Description | General purpose luminaires | Road and tunnel lighting | Flood lighting |

| EN/IEC 55015:2019 | Limits and methods of measurement of radio disturbance characteristics of electrical lighting and similar equipment | √ | √ | √ |

| EN/IEC 61000-3-2: 2019 | (EMC) – Part 3-2: Limits – Limits for harmonic current emissions (equipment input current ≤16 A per phase) | √ | √ | √ |

| EN 61000-3-3:2013 | Electromagnetic compatibility (EMC) – Part 3-3: Limits -Limitation of voltage changes, voltage fluctuations and flicker in public low-voltage supply systems, for equipment with rated current ≤16 A per phase and not subject to conditional connection | √ | √ | √ |

| EN 61547:2010 | Equipment for general lighting purposes. EMC immunity | √ | √ | √ |

EN 60598-1

EN IEC 60598-1:2021/A11:2022 was revised by CENELEC on February 16, 2022. All luminaires shall comply with EN IEC 60598-1:2021 which include the following:

- Equipped with marks of compliance with this standard. The durability of the marking shall meet the test requirements defined in the standard EN IEC 60598-1:2021.

- Luminaires should be assessed for blue light hazards according to the technical report IEC/TR 62778:2014. This requirement is contained in the standard EN IEC 60598-1:2021.

- The power supply voltage of the lamp is 230v. For lamps with rated input power ≤ 50w, the circuit power factor of lamp power supply λ ≥ 0.90, for lamps with rated input power > 50w (100% power, initial luminous flux of lamps), the circuit power factor of lamp power supply λ ≥0.95. The power factor of the power supply circuit for dimming lamps (dimming to 20% of the initial luminous flux) should be λ ≥ 0.60.

- The luminaire including all electronic equipment shall operate without failure at an ambient temperature of -35 ≤ ta ≤ +25°C.

- The protection level of road and railway lamps should be clear, class I or class II. At present, most European countries prefer Class II.

- External wiring shall be suitable for outdoor use.

- For the external wiring of all road lighting devices, the nominal cross-sectional area of the cable conductors should be ≥ 1.5 mm2. The wires shall have stranded conductors according to standard EN 60228:2005.

EN 60598-2-1, EN 60598-2-3, EN 60598-2-5

In addition to 60598-1, there are also standards for specific lamps. For example, fixed general purpose luminaires should meet the 60598-2-1 standard, luminaires for road and street lighting should meet the 60598-2-3 standard, and floodlights should meet the 60598-2-5 standard. Due to the large amount of content involved, we will not expand it here.

RoHS Directive

Luminaires shall comply with directive 2011/65/EU on the Restriction of the use of certain Hazardous Substances (RoHS) in electrical and electronic equipment and shall meet the requirements specified in the directive according to the standard EN IEC 63000:2018. Standards other than EN IEC 63000:2018 may also be used to demonstrate compliance with the directive. RoHS is a mandatory standard formulated by the EU legislation, which was officially implemented on July 1, 2006. It is mainly used to standardize the material and process standards of electronic and electrical products, making it more conducive to human health and environmental protection. . The purpose of this standard is to eliminate lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and polybrominated diphenyl ethers in electrical and electronic products. The fulfillment of RoHS requirements shall be through the manufacturer’s Declaration of Conformity (DoC) related to the CE marking and its technical file.

Structural requirements

General requirements

- All electronics of the luminaire shall be protected from moisture and corrosion throughout the rated life of the luminaire.

- According to the standard EN IEC 60598-1:2021 and EN 60529:1992, the degree of protection of the lamp should be IP66. The degree of protection of the luminaire shall remain unchanged to IP66 throughout the rated service life of the luminaire (including proper maintenance).

- When an appropriate external cable is fitted, the cable entry shall provide protection against dust or moisture according to the ingress protection rating of the luminaire.

- The edges of the cable entry shall be rounded with a minimum radius of 0.5 mm.

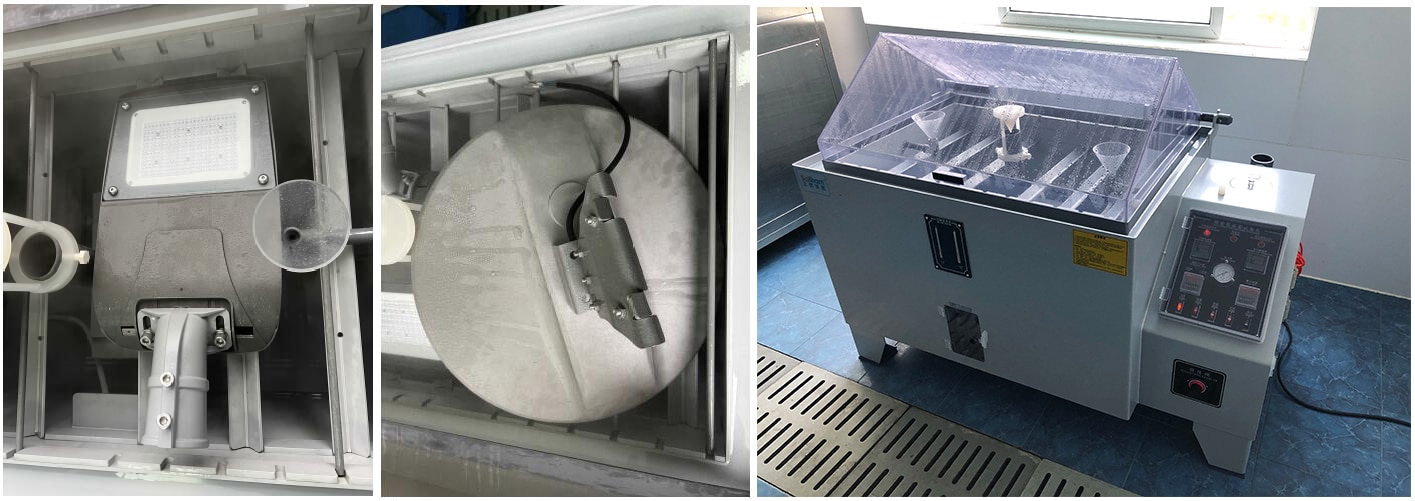

- The service life of the lamp housing should be at least the same as the rated service life of the lamp, and the corrosion resistance of the lamp should meet the requirements. Salt spray test (Salt Spray Test) is an environmental test that mainly uses artificially simulated salt spray environmental conditions created by salt spray test equipment to assess the corrosion resistance of products or metal materials. The salt spray test is divided into two categories, one is the natural environment exposure test, and the other is the artificially accelerated simulated salt spray environment test. The artificial simulated salt spray test includes neutral salt spray test, acetic acid salt spray test, copper salt accelerated acetate salt spray test. Evaluate and compare the level of corrosion resistance of metallic materials with and without corrosion protection, the results are presented as performance rating and rating of types of coating deterioration. After the test , if the defect area is less 0.1%, and there are very slight blistering on surface of street light, then we got the Rp is 9 and Ra is vs G.

- Luminaire enclosures (excluding plate glass, seals, vents, nuts, screws, latches, etc.) shall be made of die-cast aluminium, extruded aluminium, or stainless steel.

- The luminaire should not be disposable, i.e. it should be possible to easily replace the LED power supply, LED module and optical lens of the luminaire.

Additional street lighting requirements

- According to standard EN 62262:2011, road luminaires have a degree of protection against external mechanical impacts of at least IK08.

- Road luminaires shall be made of plate glass, and the service life of the plate glass shall be at least the same as the rated service life of the luminaire. Plate glass for road luminaires shall be part of the sealed luminaire housing.

- Luminaire with post top or side entry installation shall be constructed of die-cast aluminum, extruded aluminum, or stainless steel. It should be provided with 2 galvanized nuts and flat washers.

- The luminaire shall be suitable for mounting on Ø 60mm and Ø 76mm post top light fixtures, Ø 42mm and Ø 60mm side entry light fixtures. Luminaire pole top or side entry fixtures shall comply with standard EN 40-2:2005. The inclination angles of the luminaires are at least 0°, 5° and 10°, and the angles of the post top lights are at least 0° and -5°. Side entry lights are at least 0° and -5°. The adjustment of the inclination angle should be carried out in steps of 2°, 5° or 5°.

ZGSM street lighting solution with certification- CE EMC and LVD

ZGSM can provide various street lights with good quality and these lamps are certificated by third party such TUV and SGS. The certificates which we have includes CE EMC, LVD, CB, ENEC, ENEC+ ( What’s ENEC plus? ) and UL. Below we list the different ZGSM street lights, along with those certificates and reports issued by third parties.

In addition to general safety and structural compliance for outdoor lighting, when exporting or supplying internationally, ensure that fixtures meet relevant certification standards — see our SASO Certificate – LED Street Light & Flood Light page for specific requirements under SASO for AC/solar LED street lights and flood lights.

Summary

When trying to bring various products into the European market, it is critical to understand the compliance path for each type of device. It is up to the manufacturer to determine the applicable standards and directives applicable to a given product before determining the appropriate conformity assessment module relevant to the product classification. Only after the product has undergone risk analysis and safety assessment can the product be put on the market and used by consumers. That is why, in this blog, we will try to clarify the corresponding standards for LED lighting products, especially EMC directive and low voltage directive. At the same time, we also explained the knowledge of LED product structure. Combined with the previous blog (introduction to the performance requirements of LED lighting equipment), we hope that the target groups in the LED industry(purchasers, tenderers, lighting designers, manufacturers and contractors), will have a better understanding of the technical specification of LED lighting products, so that they can better serve your own projects.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483