Why high CRI is always low luminous efficacy?

Why high CRI is always low luminous efficacy?

Introduction

LED technology was first discovered at the beginning of the 20th century, and was initially used as indicator lights in electronic products. At the end of the 20th century, scientists utilized red, green and blue LEDs to produce white light, which was gradually applied to the lighting industry. Compared with traditional light sources, LED lamps are widely used in industrial, commercial and outdoor lighting because of their high energy efficiency, long life and high color rendering index (compared with high-pressure sodium lamps and some halogen lamps). With the increasing demand for lighting quality, people are no longer only concerned about whether the lighting provides sufficient illumination/brightness, but also pay more attention to the quality of the lighting, including uniformity, glare (What’s glare and how to reduce it? ), CRI and energy efficiency, etc. In this paper, we will focus on what is the CRI of LED lighting and what is the energy efficiency of LED lighting. In this article, we will discuss what is CRI and luminous efficacy, and how to improve CRI, and we will also discuss the relationship between CRI and luminous efficacy, as there is often a conflict between the high CRI and high luminous efficacy, for example, to improve the CRI will often be at the expense of some of the luminous efficacy, on the other hand the pursuit of high luminous efficacy may lead to a decline in CRI. Next, we will expand one by one to explain it.

What’s CRI?

Color rendering index (Ra /CRI) is a measure of the ability of the light source to the object’s true color reproduction index, the range from 0 to 100, the higher the value indicates that the more accurate color reproduction. The International Commission on Illumination (CIE) sets the color rendering index of sunlight (natural light spectrum) at 100, and specifies 15 test colors, using R1-R15 to represent the display index of these 15 colors respectively. When comparing a light source with a specified reference light source (sunlight), we can derive the difference in color coordinates between the 8 standard color samples (R1-R8) under the light source to be tested and the reference light source, and then use a specific formula to calculate the special color rendering index (Ri) for each color sample, and the CRI (Ra) is the arithmetic mean of the color rendering indices of these 8 standard color samples. Extended color rendering indices (i.e. R9-R15) are sometimes used to evaluate the effectiveness of a light source in rendering saturated colors (e.g., reds and blues), and in some application scenarios may have specific requirements. Ideal CRI values of >90+ provide excellent color rendering for high-end applications, while CRIs of 80-89 are suitable for most residential and commercial uses. Below 80, the luminaire has poor color rendering and is usually used for industrial or roadway lighting (What we shall care in street lighting?) where color accuracy is not required.

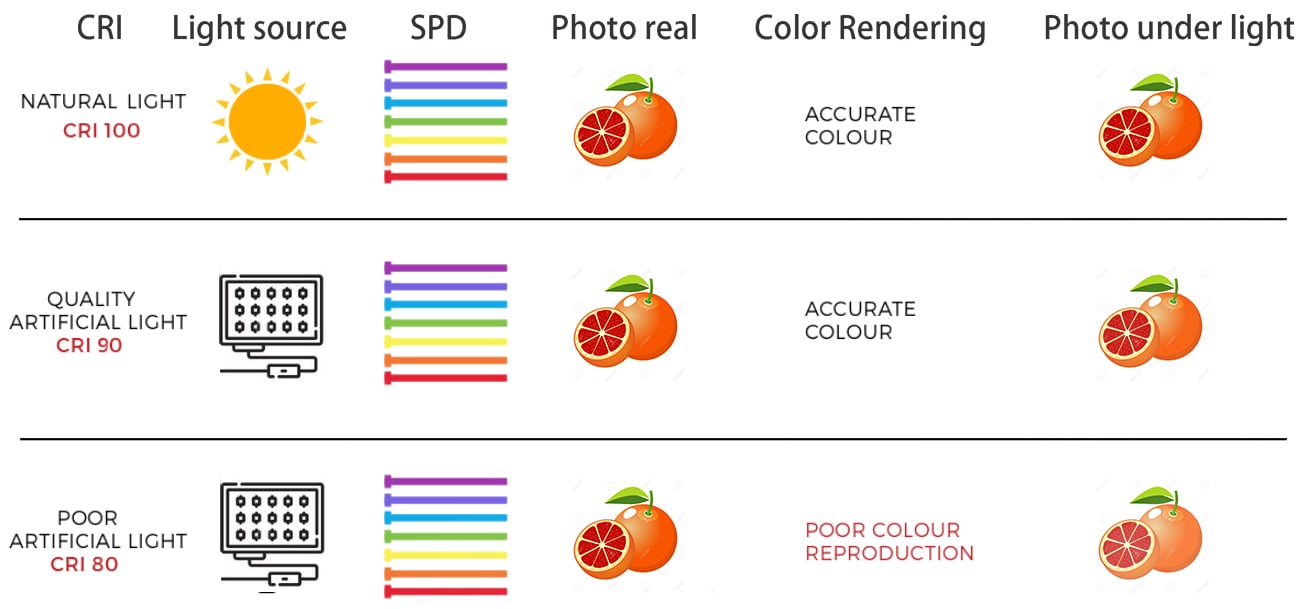

The above explanation may be a bit abstract, so we will use pictures to show it below. We generally believe that the CRI of natural outdoor light will reach 100 points, so in essence, we use CRI to test and compare artificial light (LED light – find more about ZGSM LED lights) and sunlight. For example, if you observe a grapefruit in orange in daylight, you will see a brightly colored grapefruit. This is because the spectrum of natural light contains all colors, and when the light hits the grapefruit, the light except yellow is absorbed, and what you see is the reflected yellow. The same orange grapefruit, if observed under a LED light with low color rendering index, will not appear bright orange in the human eye due to the lack of yellow or the low proportion of yellow in the spectrum. On the contrary, if a high-quality LED light (whose spectrum is as close to natural light as possible with high CRI) is used, you will see a bright orange grapefruit.

How to get LED light with high CRI?

There are currently three mainstream solutions to improve the color rendering index of LED lamps. The first is to use different phosphor ratios; the second is to reduce the PN junction temperature and improve the adaptability of phosphors at high temperatures; the third is to use color compensation technology (using red LEDs or amber LEDs to compensate for the color rendering index of LEDs). Let’s explain them one by one.

Use different phosphor ratios

The most direct and effective way to improve the CRI of LED light sources is to make the spectrum of white light LED as close to the spectrum of sunlight as possible, that is, the closer the spectrum is to the reference light source, the higher the CRI. In other words, the more comprehensive the spectrum of light emitted by the LED light source in the visible light range, the higher the CRI will be, and the closer the CRI of the light source is to 100. In the early days of LED light source development, it was difficult to improve the CRI of white light LED light sources, mainly because the most efficient and classic white light implementation scheme of blue light LED chip + yellow phosphor (YAG) lacked the color of the saturated red (i.e. R9) part, and also lacked the cyan part near 490nm, resulting in more missing spectrum emitted by the entire LED. Later, with the development of technology, mainly the rapid development of phosphor technology, the application of red phosphor technology has become more and more mature. Now the CRI of white light LED light sources with red phosphor added can exceed 90 or even close to 100. In practical applications, we often need to find such high CRI LED chips, which is relatively easy for most suppliers to do. But when customers have requirements for lighting efficiency, we have to choose between high CRI (high CRI will lead to high TLCI sometime, find more about CRI vs TLCI) and high lighting efficiency. If you need both, you have to pay more to get high-quality (high CRI + high lighting efficiency) LED chips.

Reduce the PN junction temperature

Theoretically, the white light produced by the blue LED chip combined with phosphor is indeed close to natural light. But practice is different from theory. This difference is mainly caused by heat. Heat will have an obvious effect on the phosphor. As we all know, high-power LEDs of outdoor lights ( street lights, flood lights, sports luminaires ) will constantly generate heat during the working process, while the cooling part will constantly radiate this heat out. As the temperature rises, the phosphor activity in the LED chips will be reduced, especially in the red part of the luminous efficiency decreases more obviously, ultimately leading to changes in the spectral distribution of the LED chips, that is, the CRI becomes lower. On the contrary, when the temperature drops, the phosphor activity of LED chips will rise, that is, the red part of the light-emitting enhancement, so that the spectral distribution is more continuous, the LED color rendering index (CRI) will also rise. Therefore, in practical applications we need to pay attention to the heat dissipation of the lamps to ensure that the LED chips work at lower temperatures, which in turn reduces the negative impact of high temperatures on the phosphor. In addition, if you observe the LM82 test report, you will also find that high temperatures will lead to a reduction in the luminous efficiency of the LED lamps, for the reasons explained earlier, namely, that the activity of the phosphor is reduced.

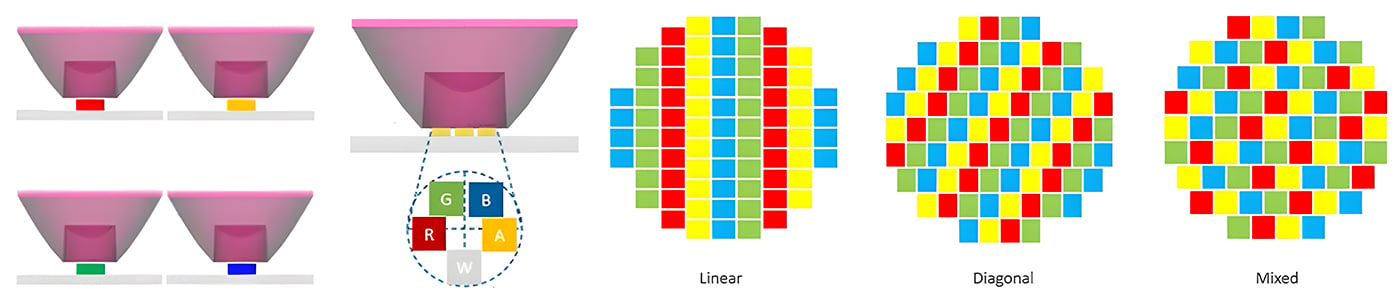

Use color compensation technology

Color mixing technology significantly improves the color rendering index (CRI) of LEDs by combining LED chips of different wavelengths (such as red, green, blue, etc.) or optimizing phosphors to expand the spectral range of the light source and make it closer to the spectral distribution of natural light. This method can make up for the deficiencies of red and green light in the traditional LED spectrum and enhance color reproduction capabilities. However, color mixing technology has many challenges in terms of cost and process complexity. This technology is similar to RGB lighting solutions (ZGSM RGB bollard light), which usually require more LED chips to achieve white light lighting. When used to improve the color rendering index, the light output (luminous flux) of LEDs of different colors needs to be precisely adjusted to simulate the continuous spectrum of natural light, which inevitably increases costs and brings technical complexity.

What’s luminous efficacy?

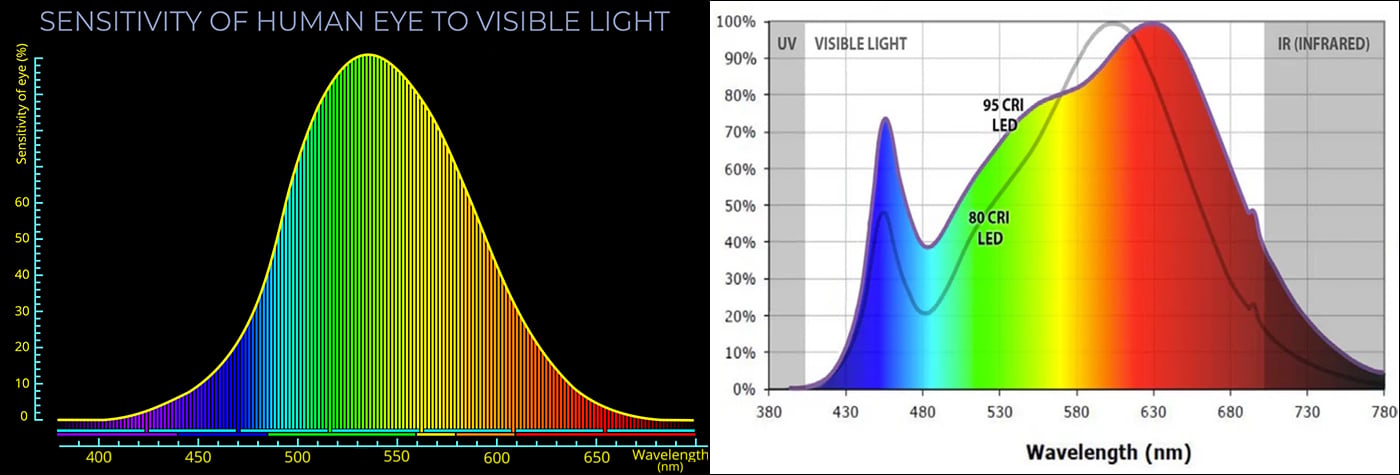

Luminous efficacy is defined as the ratio of luminous flux to input electrical power (lm/W), that is, the luminous flux generated per watt of electrical consumption. The calculation formula is luminous efficacy = lumen output / wattage of luminaire. From this we know that luminous efficacy is determined by two factors: luminous flux and input wattage. The unit of luminous flux is lumen (lm). The larger the value, the more light the light source emits. However, generating luminous flux requires electrical power in watts (W). The higher the ratio of luminous flux to lamp wattage, the more efficient the light source is in converting electrical energy into light energy, which means that less electrical energy is consumed at the same brightness and the luminous efficacy of the lamp is higher. The luminous efficacy of different light sources (such as incandescent lamps, fluorescent lamps, and LEDs) varies greatly. The current mainstream LED luminous efficiency can reach 230lm/W. However, different wavelengths of light (different spectra) have different luminous efficiencies. This is because the human eye has different sensitivities to different wavelengths of light. It is most sensitive to green light (wavelength of about 555 nm), while it is less sensitive to blue and red light. In the previous section, we mentioned that changing the proportion of different colors of light in the light can improve CRI. It is for this reason that excessively increasing red light to improve CRI will inevitably lead to a decrease in luminous efficiency.

How to improve luminous efficacy?

Improving luminous efficacy is the core goal in the design and manufacture of lighting systems, involving the optimization of multiple key factors. Through the calculation formula, we can know the two main directions of improving luminous efficacy. The first is to maximize the luminous flux emitted by the LED chips (under the same wattage), and the second is to minimize the wattage consumed by the lamp. For the first point, we need to choose LED chips with high luminous efficacy, and at the same time reduce the light loss in the lamp, including the trapped light inside the luminaire caused by the lens, reflector and lamp structure. For the second point, we need to reduce the power consumption other than the LED chips, and its consumption mainly comes from the power supply, so we need to optimize the electrical parameter design and select high-quality LED drivers (power factor correction PFC technology) and so on. In addition, we need to pay attention to the heat dissipation of the lamp. Generally speaking, the higher the operating temperature (Tj) of the lamp, the lower the efficiency of the lamp, which is consistent with the CRI requirement. At the same time, good heat dissipation is also conducive to slowing down light decay and thus extending the life of the lamp. If you are interested in more about how to improve the luminous efficacy of lamps, you can move to the blog “How to improve luminous efficacy?“.

What‘s the relationship between CRI and luminous efficacy?

As humans, we see light with our eyes. These special biological sensors have a lot of working parts. The iris controls the amount of light that enters the eye by adjusting the size of the pupil, which can expand from a minimum of 2 mm in diameter (in bright conditions) to a maximum of 8 mm in diameter (in dark conditions). When there is plenty of light, it closes to protect the sensitive cells in the eye; when there is not enough light, the iris controls the pupil to expand to allow more light in. In our eyes are millions of tiny sensory cells called rods and cones. Rods are responsible for sensing light in low light conditions (scotopic vision), while cones perform best in bright conditions (such as daylight) and are responsible for color perception (photopic vision). There are three types of cones, each sensitive to a specific wavelength of light – short-wave sensitive cones (S-cones, about 420-440 nanometers, sensing blue light), medium-wave sensitive cones (M-cones, about 530-540 nanometers, sensing green light), and long-wave sensitive cones (L-cones, about 560-580 nanometers, sensing red light). The figure below is the photopic spectral light efficiency function, we can see that the cones reach a peak at 555 nanometers, which indicates that the cone cells of the eye are most sensitive to yellow-green light with a wavelength of 555 nanometers. Compared with other wavelengths of light, this wavelength of light produces the highest brightness.

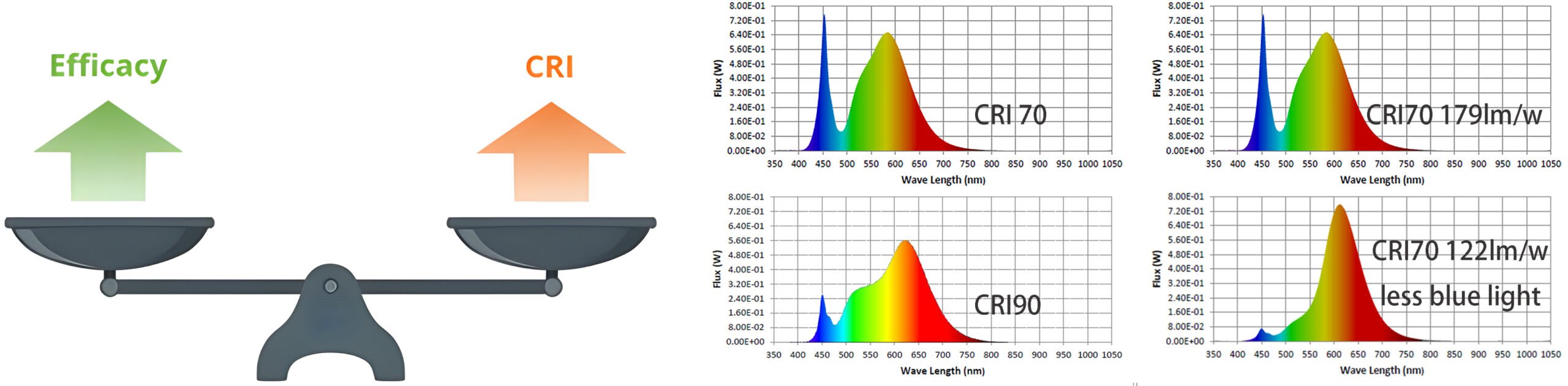

Through the relevant knowledge in the section “How to improve CRI of LED light”, we can understand that adding phosphors to LED chips can improve CRI. White light LED lighting usually has a low CRI due to the lack of saturated red (i.e. R9) components and cyan components near 490nm. By adding red phosphors, the color rendering index of LED can be improved to 80-90 or even higher. However, there is a contradiction here: different wavelengths of light have different luminous efficiencies. Although excessive addition of red phosphors can improve CRI, it will reduce the light efficiency. In addition, many countries are now beginning to limit the blue light (Know the blue light in LEDs) components in LEDs (for example, promoting the use of 1800K low color temperature LEDs). As can be seen from the figure below, this adjustment has caused a significant change in the spectral composition – the proportion of green light has been greatly reduced, resulting in a decrease in the overall light efficiency of the lamp. At the same time, the reduction in the proportion of blue light has also had a negative impact on CRI. It is precisely because of the intricate constraints between these parameters that the development of LED technology still faces many challenges and there is still a long way to go in the future.

Temperature also has an impact on CRI and luminous efficacy, and in the section on how to improve CRI and efficacy, we know that lower temperatures are better for CRI and efficacy, and ZGSM has always been committed to the optimization of luminaire heat dissipation in this regard, and from the structural design, to the Ts-point temperature test, and the third-party test report, ZGSM has strict requirements to ensure that the luminaire temperature is in the right range. Similarly, a reasonable temperature is also very favorable to slow down the light decay of the luminaire, if you are interested, you can refer to the corresponding blog “What’s light decay?“.

To summarize, in general, the lower the CRI, the higher the lumen output. When you look at the datasheet for the Lumileds 3030 LEDs, you will see that when we raise the CRI from 70 to 80, the lumen output will drop about 6%. When the color rendering index is increased from 80 to 90, you will see that the lumen output will drop about 14-15%. We can see that we have to make a choice between CRI and luminous, if you need a high color rendering index, then you need to reduce the requirement for luminous efficiency. While the task of how to improve CRI and light efficiency can only be left to the LEDs manufacturers for further research. One is the mixing of phosphors, and the other is to reduce the accumulation of temperature in LED chips (More about working temperature of LEDs and LED driver). As a luminaire manufacturer, we need to truthfully inform our customers of such a fact, and at the same time we should reasonably design the luminaire in order to avoid the adverse effects of high temperature on CRI and luminous. ZGSM has optimized technical solutions to maintain a balance between efficacy and high CRI spectrum, and has developed different solutions. Below are ZGSM’s different LED products. If you are interested, you can learn more.

Summary

This article mainly introduces two key factors in the field of LED lighting: color rendering index (CRI) and luminous efficacy. The former measures the ability of a lamp to display the true color of an object. We know that the CRI in a lamp can be improved by using different phosphor ratios and optimizing the heat dissipation of the lamp. The latter is the efficiency of the lamp in converting electrical energy into light energy. By using efficient LED chips and high conversion efficiency LED drivers, we can improve the luminous efficacy of the lamp. However, users often need to choose between the high CRI and high luminous efficacy. If a lamp with high CRI is required, the efficiency of the lamp will be low. If a high efficiency solution is required, we often need to make concessions on CRI. Of course, you can also choose a high CRI and high efficiency solution, but you often have to pay more at this time. ZGSM’s LED lighting solution can achieve high color rendering index( as per project requirement ) and high efficiency LED lamps by selecting high color rendering index lamp beads and optimizing lamp design, such as CRI80, light efficacy>160lm/w. The solution involves road lighting, stadium lighting (More about ZGSM sports lighting solutions), parking lot lighting and industrial lighting, etc. If you are interested in our lighting solutions, please consult us for more information.

Related Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483