Industrial lighting design – workshop or warehouse complex

Introduction

There are many industrial parks all over the world. The roads in the park need to be illuminated for drivers to drive safely. Factories and warehouses in the park need to be illuminated to utilize workers to do their jobs better. The parking lot in the park needs to be illuminated to facilitate the safety of life and property. The warehouse complex, the operation area in the park, needs to be illuminated to facilitate the loading and unloading of workers and the transfer of goods. This article mainly explains how the lighting design and lighting control should be done for the indoor working area of the factory in the industrial park and the working area around the factory.

Working areas inside the factory: The size, structure, environment and purpose of factory indoor areas vary greatly, which means that there is no single solution for different industrial lighting. Working area outside the factory: The peripheral structure of the factory has two types: half aisle and fully open. In the case of half aisle, you can refer to the indoor area. For fully open one, we generally use floodlights or street lights to achieve lighting, the difference between the two is quite large. Therefore, the use of lighting design is necessary.

In addition, we should adopt different standards for different jobs. We can refer to EN12464-1 to view the lighting standards for different work tasks. Due to the limited space, we will not briefly introduce the corresponding lighting standards here. If you are interested, you can contact us to obtain the standards or check the official website of EN standard.

Problems of industrial lighting

Illumination does not meet the job requirements(Too high or too low power): Insufficient power leads to insufficient illumination, which is not conducive to improving production efficiency and operation safety. Too high power leads to too bright environment, which will lead to waste of resources.

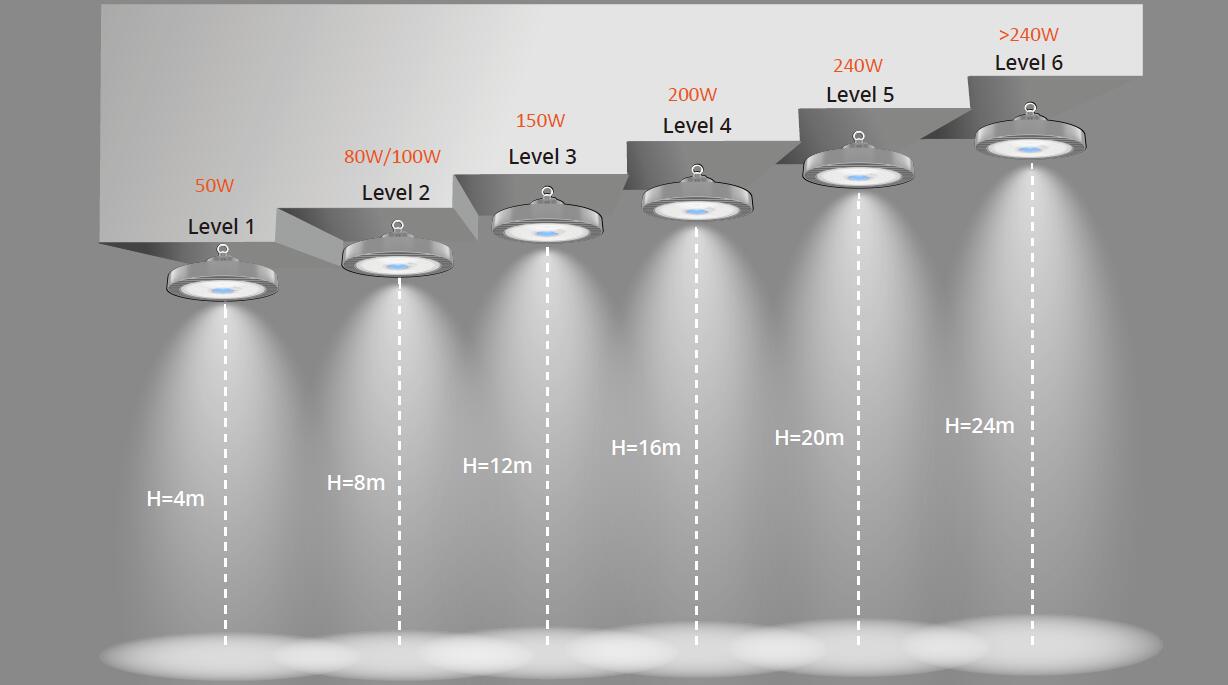

The height of the building leads to insufficient brightness: the range of industrial sites is usually 4 to 12 meters, and the higher can get 20 meters and above. The illuminance of the luminaire will be affected by its installation height, the higher the ceiling, the lower the overall illuminance. At this time, we either increase the wattage of the lamps or reduce the installation height of the lamps.

The protection performance of lamps does not meet the requirements: For dusty, humid, flammable and potentially explosive environments, we have to choose a high IP level (protection level) to ensure that they meet lighting safety standards. If the IP level is not enough, the service life of the lamps will be shortened, and serious accidents will occur.

Discomport or disable glare: Lighting systems are fundamental to the built environment, providing adequate visibility indoors and at night. However, poorly placed industrial lighting fixtures can cause glare, which can range from discomfort to impaired vision. In simple terms, glare can be defined as the visual difficulty experienced when a bright and concentrated light source is in the direct line of sight. Glare creates a perception of brightness in the field of vision to which the human eye cannot adapt, resulting in nausea, discomfort and even loss of vision. The generation of glare is directly related to the optical design, installation height, layout and use environment of the lamps.

The following are frequently asked questions about industrial lighting. That’s why we need the help of lighting design.

For workshop lighting

Factory buildings generally adopt steel structures and have high ceilings. The main reason is that the construction period is short, which can reduce the investment in labor costs. At the same time, the performance of fire prevention and corrosion resistance is satisfactory. In addition, steel structure houses are easy to recycle and have little impact on the environment. Therefore, steel structures are widely used and have always been the choice of production workshops, warehouses, etc., for the assembly and periodic storage of general machinery. Below we only discuss the lighting design guidelines for using high bay lights in production workshops in general environments.

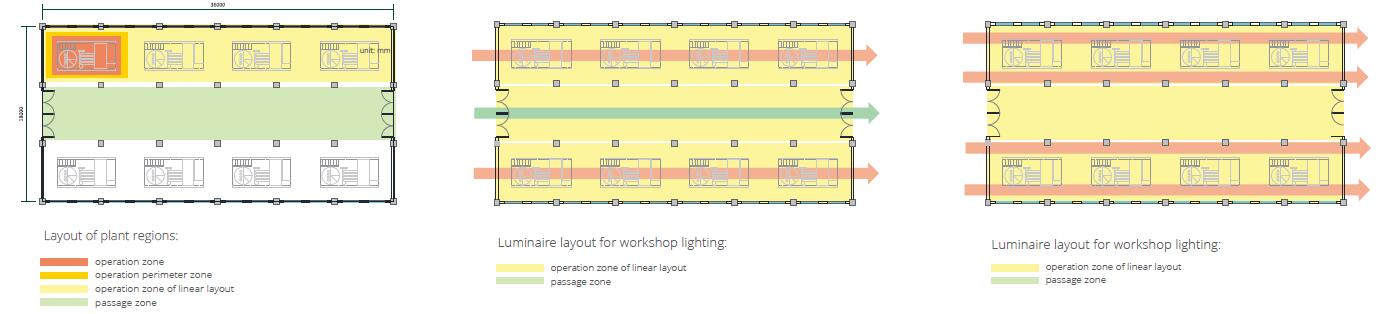

Layout of workshop lighting

Generally speaking, the production raw materials or equipment are located in the operation area (as shown in the red box in the figure below), and the adjacent area (as shown in the orange box in the figure below) is the surrounding area of the operation. The area covered by the linear layout of these two areas (as shown in the yellow box below) is the key area of high bay lighting, and the arrangement of lamps is generally directly above this area (as shown by the red arrow in the figure below). In addition, the aisle in the work area generally also needs to provide lighting (as shown by the green arrow in the figure below). Of course, the requirements for the lighting of the aisle are not high, and the lamps in the work area can provide certain lighting for the aisle, so we sometimes don’t need to install additional aisle lights (as shown in the right figure below).

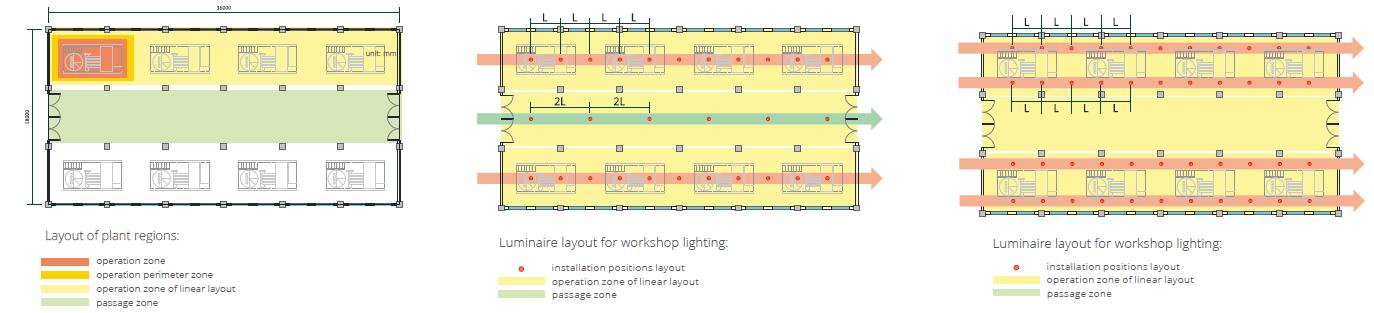

Space of workshop lighting

In general, work area lighting requirements above equipment are more stringent than aisle lighting. When we try to install the high bay lamp, more lamps should be set in the yellow area (that is, the spacing is smaller), while fewer lamps should be installed in the green area (that is, the spacing is larger). For example, in the figure below, the distance between lamps in the work area is L, while the distance between lamps in the aisle area is 2L. Of course, the distance and position between the installed highbay lamps can be determined according to the actual situation. For example, the position of the suspension point on the steel structure sometimes determines that the position of the lamp arrangement is fixed. Or the lighting of the work area can cover the passage lighting without affecting its own needs, then we don’t need a separate passage light (such as the right picture below).

Height of workshop lighting

Factories generally have different heights depending on the operating project, so the wattage (lumen output) of the installed high bay light should be adjusted according to the distance between the ceiling and the ground to obtain the best lighting effect. In the figure below, we list the power options corresponding to different floor heights (here we assume that the luminous efficacy of all lamps is around 150lm/W). Generally, the higher the installation height, the greater the wattage of the lamp we need. Of course, when the installation interval and illuminance requirements are different, we have to adjust the wattage of the lamps accordingly, which cannot be generalized.

For outdoor area lighting(workshop or warehouse complex)

Semi-outdoor and corridor lighting application:

For the lighting of this type of area, we believe that the arrangement of LED lamps can be made with reference to the lighting characteristics of the indoor work area. The main difference is that the lighting of this area is generally carried out at night, so the illuminance does not need to be as high as indoor lighting. Generally 100lux is enough.

Loading and unloading docks lighting application:

Factories generally have areas dedicated to loading and unloading goods. Lighting fixtures in this area are generally installed on the exterior walls of buildings. When there are loading or unloading jobs in some areas at night, we needs to light up some lights to achieve the working brightness for the workers to do their job. When the area is not working due to weather or other reasons, there is no stevedores and vehicles, it is only necessary to light up the lights for the walking staff on duty. This mainly involves lighting control, so we won’t give too much brief introduction here. Let’s talk about the application selection of height, spacing and installation angle in the outdoor area of the factory.

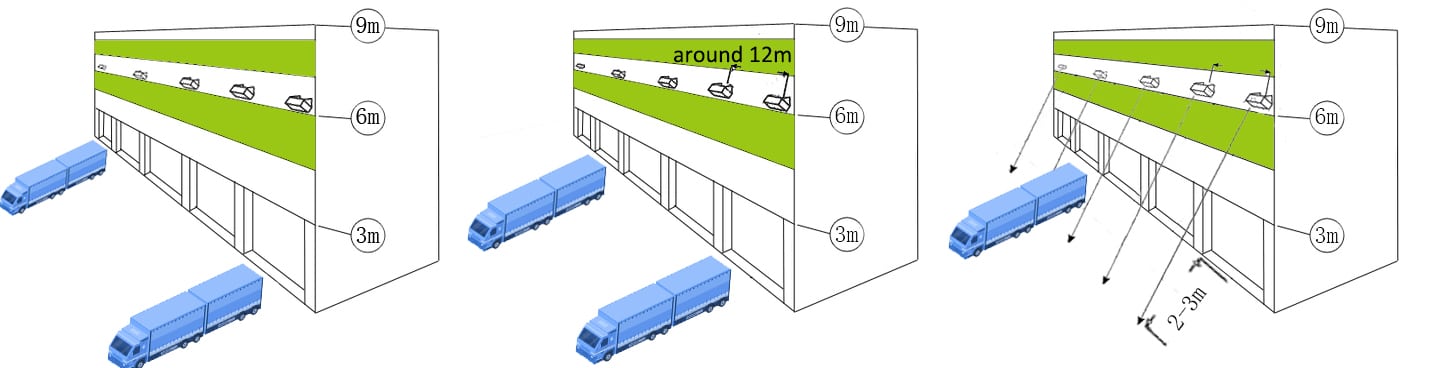

Height of outdoor area lighting

Generally speaking, the installation height of the lamps in the outdoor area is directly related to the ceiling height/wall height, which is generally around 4 to 8 meters. It can be about 3 meters for lower ceiling or it can be 10-12 meters for higher ceiling. ZGSM believes that the height should be as high as possible if the situation permits. There are two main reasons: 1. Avoid glare caused by too low installation height. 2. The higher the installation height, the more uniform the illumination is generally, which is conducive to loading and unloading operations. In the picture below, we recommend that the installation of the perimeter of the plant be 6 meteers. Of course, if the installation is convenient, we can also recommend customers to install the lamps at a height of 8 meters.

Space of outdoor area lighting

In order to obtain better uniformity of illumination, we generally recommend that the spacing is about 2-3 times the installation height when the lamps are going to be installed. If the spectral design of the luminaire is reasonable, the spacing setting can reach 3-4 times the installation height. Of course, if the illumination required for the operation of the loading area is high, we can not only increase the wattage, but also shorten the installation distance appropriately. Usually, we need to choose between increasing the wattage or shortening the installation distance, so when the installation height is high, we will have more choices, and it will be handier when doing lighting simulation.

Beam angle(aim point) of outdoor area lighting

When the installation height and spacing are fixed, we will properly adjust the tilt angle of the lamp installation. Generally speaking, this angle should be below 30 degrees. Of course, if you use an asymmetric spectrum (a forward throwing optic), the installation height is high enough, and the back throwing light of the lamp is almost negligible, we can set the tilt angle to 0. In this ideal situation, the illuminance is very uniform, with less light pollution and less glare. When it comes to practical application, we think that the angle should be around 20 degrees. This will make the backlight reach the loading and unloading area instead of the wall, and the irradiation range will be wider to reduce dark spots that may cause accidents. At the same time, we can control light pollution and glare within a reasonable range.

ZGSM industrial lighting solution

| Performance summary of Heilos series |

| Initial Lumens: Up to 38000 lumens |

| Input Power: Up to 200W |

| Efficiency: 140-190lm/W |

| CCT: 2700K, 3000K, 4000K, 5000K, 5700K |

| Main features: Smart control |

| Application: Workshop lighting, Warehouse lighting |

| Performance summary of Primo series |

| Initial Lumens: Up to 23250 lumens |

| Input Power: Up to 150W |

| Efficiency: 155-165lm/W |

| CCT: 2700K, 3000K, 4000K, 5000K, 5700K |

| Main features: ATEX certificated |

| Application: Canopy lighting, Landing dock lighting, Area lighting |

| Performance summary of Rilfe series |

| Initial Lumens: Up to 38400 lumens |

| Input Power: Up to 240W |

| Efficiency: 140-170lm/W |

| CCT: 2700K, 3000K, 4000K, 5000K, 5700K |

| Main features: Tool-free open |

| Application: Main roads, Area lighting, Parking lot |

| Performance summary of Halo series |

| Initial Lumens: Up to 21750 lumens |

| Input Power: Up to 150W |

| Efficiency: 135-150lm/W |

| CCT: 2700K, 3000K, 4000K, 5000K, 5700K |

| Main features: 6 ways of installation |

| Application: Small roads, Parking lot, Landscape lighting |

Summary

Above we have introduced the matters that should be paid attention to in the lighting design of industrial parks, and hope that everyone can use them in future applications to better serve their own projects. There are many industrial parks, and ZGSM is committed to serving more customers and providing them with one-stop lighting services. Our LED products include high bay lights, flood lights, street lights and garden lights, which can meet the lighting needs of most industrial parks, including workshop lighting, unloading area lighting, internal road lighting and parking lot lighting. In addition, we also provide lighting design services. As long as you have project drawings, lighting requirements and lighting areas, we will provide lighting design and recommend suitable lighting fixtures for customers based on different lighting standards or customized needs of customers. Customers can comprehensively choose their own lighting solutions through lighting design and our lighting fixtures. Get in touch with us now.

Rated Products

Related Blogs

Related Cases

People also ask

Author introduction

Hello Customers,

My name is Taylor Gong, I’m the product manager of ZGSM Tech. I have been in the LED lights industry for more than 13 years. Good at lighting design, street light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Email: [email protected] | WhatsApp: +8615068758483